March 31, 2015 – Look at the picture below. These hyper-real teeth were produced using a 3D printer. The disruptive impact of 3D printing on dentistry is just starting. From replacing missing teeth with implants to bridges, crowns and orthodontia, 3D printer manufacturers are producing new models and materials specifically designed to be used by practicing dentists in office. What this may mean for the dental laboratories that traditionally produce objects like the one seen below should give them all pause. They may go the way of the typewriter and film cameras if they do not adapt.

Today a dental laboratory represents a significant add-on cost to any dental practice. Every crown, bridge, implant or model a dentist uses is produced by them. The costs are factored into every dental bill patients receive and they are not inexpensive. when I had a crown done a few years ago, the total cost for all the work amounted to well over $2,000.

The dental laboratories employ skilled labor to produce crowns, dentures, partials and full sets of false teeth. The cost to an individual dental practice, depending on the volume of work, can amount to $100,000 in added overhead per year. And if a dentist takes the laboratory work in-house, the one-time cost of the equipment to do the work could easily reach $100,000 using traditional technologies.

But not anymore. The top-model 3D dental printers today sell for about $20,000 including a supply of materials. That’s one-fifth the cost of outsourcing the work to a dental laboratory. And when you consider that the cost of 3D printers is dropping to the point where they are becoming almost a commodity, the incentive for dentists to invest in them seems almost irresistible.

What can a dentist do with one of these 3D printing technologies in house? Here are just a few applications:

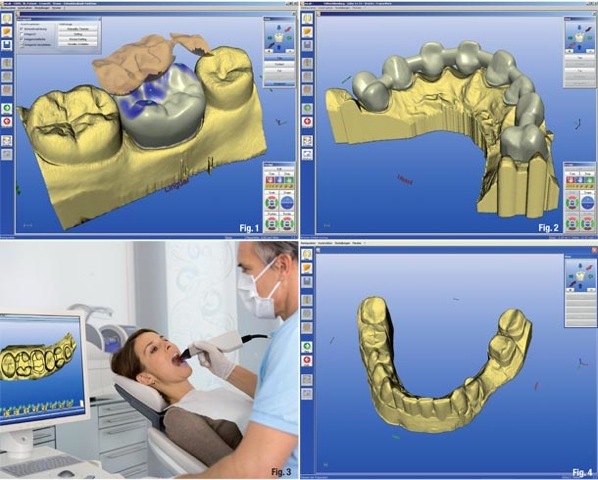

- Replace or repair a damaged tooth. What’s involved? Scan the patients mouth (see images below) using a digital wand. Create a 3D image file of the teeth and gums. Use CAD software to design the repair. Produce the finished product using the 3D printer.

- Create a model for orthodontia. It used to be get the patient to bite into a mold filled with clay and then set it aside to harden. Then send it to an outside laboratory to produce. But not now. Using the same process as described in point #1 the orthodontist can produce a finished model right in the office.

- Create crowns, bridges and implants. 3D printers can produce the models needed as well as the finished crowns, bridges and implants. The technology is the same. Only the materials used in printing would be different.

In a recent report on CNBC the dental sector is cited as the one most likely to “mass uptake” 3D printing technology growing 515% over the next decade. And ID TechEx in a recent forecast predicted that sales of 3D printers to the medical and dental sector will top $868 million US by 2025.