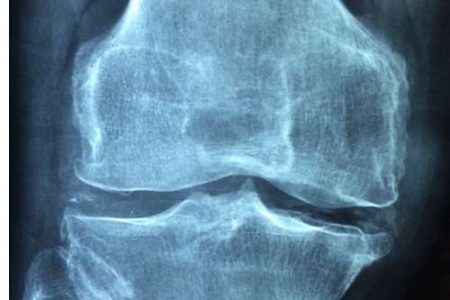

May 1, 2017 – I have less than 10% of my original cartilage mass in my left knee. It looks a bit like the xray images of a knee joint you see below. So you can imagine how interested I am in learning that researchers at Sahlgrenska Academy, University of Gothenburg, Sweden, have described their latest breakthrough, generating cartilage tissue by printing stem cells using a 3D printer. The stem cells not only survived the printing phase, but then differentiated to form chondrocytes (cartilage cells) within a cellulose matrix shaped by the researchers to fit a knee joint.

Their success is described in the journal, Nature’s Scientific Reports, in an article entitled “Cartilage Tissue Engineering by the 3D Bioprinting of iPS Cells in a Nanocellulose/Alginate Bioink.”

The source of the stem cells used came from cartilage harvested from patients undergoing knee surgery. The harvested cells were manipulated to revert back into pluripotent stem calls. These cells were then cultured to multiply and then 3D printed onto a cellulose scaffolding. After surviving printing the cells were then given growth factors to encourage them to differentiate into chondrocytes.

Stina Simonsson, Associate Professor of Cell Biology at Sahlgrenska, described how much of the research team’s effort was focused on keeping stem cells viable throughout the printing process. She pointed to the need to create a bio ink that allowed the cells to remain viable as they passed through the print head and got deposited on the cellulose scaffolding. The researchers also developed a protocol to encourage the cells to multiply before differentiating to become cartilage.

How was this done?

States Simonsson, “We investigated various methods and combined different growth factors. Each individual stem cell is encased in nano cellulose, which allows it to survive the process of being printed into a 3D structure.”

The researchers then employed a trick to make the stem cells think they weren’t alone. This was done, states Simonsson by harvesting “mediums from other cells that contain the signals that stem cells use to communicate with each other.”

The cells then multiplied in sufficient quantity before differentiating. The key issue to make differentiation work, states Simonsson, was to create large amounts of live stem cells before cartilage could be successfully grown.

The success of the Sahlgrenska experiment has enormous implications for the treatment of osteoarthritis. People suffering from degenerative joints like me may soon be able to use their own surviving cartilage cells to effect partial to full repairs.

One issue remains to be solved.

Simonsson points out that the cellulose being used to form the scaffolding as a framework for cartilage growth may not be suitable for implantation in human joints. The research team is currently seeking other materials that could be used.

Why?

Because the matrix must be both inert so that there is no rejection as well as biodegradable so that it temporarily serves as a framework for the cartilage to grow. It literally must melt away leaving only the remaining endogenous cartilage.

This should be doable based on what I saw done a number of years ago for one of my dogs, Katie, a sheltie-terrier, when she tore the meniscus in her back leg. A surgeon implanted a matrix in the leg to encourage the tear to heal and as Katie’s cells regenerated, that scaffolding melted away. Six weeks after surgery at age 12, she was as good as knew and lived with us four more years before passing away.

So I’m holding out on getting knee replacement (I’ve been a candidate for the last six years) knowing that I could regrow my cartilage because of the research done by Simonsson and her colleagues at University of Gothenburg.