Easily accessible oil and gas finds, usually referred to in the industry as conventional hydrocarbon reserves, are a thing of the past. Instead resource developers are increasingly turning to unconventional alternatives such as deep ocean exploration and extraction, the mining of bitumen deposits and oil shales, and the creation of oil products from biomass and garbage.

In 2013 Canadians will celebrate the one hundredth anniversary of the first commercial extraction of oil from what has been labeled the Athabasca Tar Sands, the oil sands of Northern Alberta and Saskatchewan. That first attempt to exploit these saturated sand deposits used hot water to separate the bitumen. To date this remains the way bitumen is extracted from oil sands.

What is bitumen? If you think of asphalt then you have a sense of what this material is like. When extracted from the sand to which it is attached it has the consistency of cold molasses and is black in colour. Bitumen is not transportable in its extracted state. Nor can conventional refineries use it to create oil and oil byproducts. It needs to undergo significant change to give it the viscosity to travel through pipeline. Upgraded bitumen from Western Canada consists of naptha and heavy and light gas oils.

The cost of upgrading, the environment in which oil sands are located, and the remoteness of the location, had made bitumen commercially unfeasible for much of the 20th century. But as oil prices rose and geopolitical considerations began to impact more easily extracted oil resources, oil sand operations became much more attractive to investors. In 1967, the Great Canadian Oil Sands Syncrude project finally came on stream extracting bitumen from the sands using similar hot water processes to those employed back in 1913. Since 1967 many other companies have started bitumen extraction operations in Western Canada. Today there are an estimated 1.7 trillion barrels of bitumen locked up in the oil sands with from 175 to 315 billion barrels of recoverable hydrocarbon product using present and developing technologies. This makes these deposits the single largest hydrocarbon source on the planet.

Is bitumen only found in Northern Alberta and Saskatchewan? No, in fact bitumen oil sand deposits can be found in countries all around the world including the United States, Venezuela, Russia, Cuba, Indonesia, Brazil, Trinidad & Tobago, Jordan, Madagascar, Colombia, Albania, Romania, Spain, Portugal, Nigeria and Argentina.

Currently the oil sands of Western Canada produce almost a half-billion barrels of oil annually. At current extraction rates the sands can remain commercially active for the next three centuries. Even if annual production were to double or triple the oil sands would remain viable for the remainder of the 21st century as a petroleum resource. Having said that there is a fly in the ointment and it has to do with the planetary impact of current oil sands production technology.

The biggest knock against bitumen is in its extraction and environmental impact. When the first commercial operations in Western Canada started the extraction process used large volumes of water to flush the oil from the sands in which it was embedded, in fact between 2 and 4.5 cubic metres for every cubic metre of oil. In Northern Alberta and Saskatchewan the major water source for these oil sands projects was one river, the Athabasca, a tributary of the Mackenzie River that flows into the Arctic Ocean. What happened to the water during the process raised further alarms. With only 10% being returned to the river and the rest being held in storage ponds that contained significant pollutants, it was only a matter of time before drawing water from the Athabasca became a public relations nightmare.

A study released at a UN climate conference in Kenya in 2006 stated that oil sands extraction projects were threatening both the quality and quantity of water in the Mackenzie River system of which the Athabasca is a tributary. The study by the Sage Centre and World Wildlife Fund-Canada pointed out that water drawn from the Athabasca had contributed to a drop in water flow of 20% at Fort McMurray according to data records from 1958 to 2003. The study further stated that oil sands projects were using 359 million cubic metres of water from the Athabasca, twice the water used by the city of Calgary, Alberta’s largest urban centre with over 1 million people. The study forecasted increased Athabasca water extraction of 50% as new projects came online. This growth in water usage was deemed to be unsustainable having a significant impact on agriculture, cities and the environment of the river system. The recommendation was to shut down any new oil sands projects until the water problems was solved.

The biggest use of water in oil sands production today is to generate steam for underground injection. Some oil sands projects are now using underground aquifers rather than the Athabasca. In many cases the water being drawn from the aquifer is not potable with a high saline content. One oil sands project, Imperial Oil’s Cold Lake facility has been able to decrease fresh water use from 3.5 barrels for every barrel of bitumen in 1985 to half a barrel per barrel of bitumen produced today.

The oil sands projects are generators of greenhouse gases. The energy to process bitumen comes from the burning of natural gas containing methane, carbon dioxide, nitrogen and hydrogen sulfide. Every barrel of synthetic crude requires enough natural gas equal to warm 1-1/2 houses daily. Natural gas is abundant and fairly clean but in burning it the carbon dioxide generated contributes to increased greenhouse gases.

The equipment needed to dig up and transport the oil sands further contributes to greenhouse gases. When added up the percentages are 13% of greenhouse gases come from the extraction process, 30% from the upgrading process and the balance from the burning of natural gas. The total amount is a staggering 29.5 megatons. That’s 29.5 million tons of greenhouse gases and as more projects come online that number may grow even higher.

The industry is looking at solutions such as carbon sequestration, that is pumping the carbon dioxide underground into stable rock formations where it can be permanently captured. The challenges of sequestration go beyond cost considerations. Carbon sequestration science is relatively new. If forecasters are right, we will need reservoirs capable of containing a trillion tons of carbon dioxide by the end of the 21st century. Salt water saturated sedimentary rock formations are currently considered the best bet for sequestration. These sedimentary formations are more than 800 meters deep so that they do not impact on potable water, and where high the depth pressure can maintain the carbon dioxide in a high-density state. But no one knows if storage of this type is sustainable for hundreds if not thousands of years. How can you account for seismic activity that could fracture the rocks creating seams where the carbon dioxide can escape.

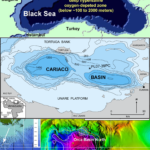

Scientists and engineers are also looking at sequestering carbon beneath the ocean floor. theorizing that the pressure from ocean water and the sediments would keep the carbon dioxide permanently locked up and incapable of entering the sea water.

The 21st century may also come up with new methods for sequestration. Some scientists cite historic carbon dioxide atmospheric concentrations as evidence that the Earth can naturally deal with the excess. They theorize that when atmospheric concentrations of carbon dioxide became high the gas was absorbed by ocean water and combined with calcium ions to form limestone.

So as long as our modern world economies and those of the developing world continue to rely on oil the oil sands will remain a significant source of production and an environmental challenge.