In a previous blog we talked about the challenges and promise of mining waste for energy. North America’s largest landfill and waste removal company, Waste Management Inc., today mines half of its 266 landfill sites in the United States and Canada for methane gas collected from decomposing garbage. The gas is used to fire turbines that generate electricity. Currently enough energy is produced to light up 1,300,000 homes and the company’s goal is to reach 2 million by 2020.

Waste Management Inc., although Houston based, has acquired companies or partnered with others overseas to deliver state-of-the-art waste-to-energy facilities for the United Kingdom and China. More recently it has launched a venture capital arm called the Organic Growth Group, to invest in companies working on breakthrough technologies that use garbage as a renewable resource.

In investing in new ventures Waste Management solves two challenges – finding technology that has commercial application for waste reduction, and being a supply source to deliver the waste it collects as fuel for these companies to exploit. As the company has made investments it has come to the realization that there is no single technology for turning waste into energy. Different waste streams exhibit different energy potential.

Three of the waste-to-energy projects that Organic Growth Group has invested in include:

Agilyx, a Portland, Oregon-based alternative energy producer that uses a patented system to gasify industrial plastics including those with contaminants and convert them into synthetic crude for diesel and other transportation fuels. The current system which is scalable converts 10 tons of plastic per day into 60 barrels (9,080 litres) of oil.

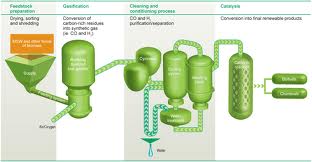

Enerkem Inc., a Montreal, Quebec company that has developed a proprietary thermochemical technology for converting waste into cellulosic ethanol, methanol and industrial chemical byproducts. Enerkem uses sorted municipal solid waste, construction and demolition wood, and agricultural and forest residue as fuel sources. Currently the company has a demonstration facility, a pilot plant, and a third plant in the planning stage in Quebec. It is building its first full-scale commercial facility in Edmonton, Alberta, and another planned for Mississippi.

Harvest Power, a Waltham, Massachusetts company, has developed a process for recycling food, yard and organic waste into renewable energy, compost and natural fertilizers. The company has developed a proprietary Covered Aerated Static Pile (CASP) system for composting. Its anaerobic digestion technology uses microorganisms to break down organic material producing bio gas containing methane and CO2. The bio gas is cleaned and can be distributed through natural gas pipelines or further compressed into liquid natural gas.