Ian Pearson is a futurist and is involved with a consulting practice called Futurizon. A recent blog posting of his at the site caught my eye and I wrote to him to ask for permission to repeat it to my readers. Ian gladly obliged me with a caveat. He states, “obviously bear in mind that my idea is only a very simple first cut….and although I think it should work, there is no proof it would….yet.”

But ideas like this are worth sharing and I invite readers to get engaged in the conversation about the feasibility of this type of renewable energy solution, one that addresses many of the outstanding issues and concerns with present wind turbine technology, and a solution that with price reductions as it scales, could make wind attractive to Developing World countries.

Ian entitles his blog entry New Type of Wind Harvester.

If we must use wind power to appease renewable fans, then at least we should do it in ways that are less irritating to humans and wildlife and a little imagination can go a long way with today’s technology compared to the primitive, almost Victorian heavy engineering used for conventional turbines. This method should be a lot quieter, less visually intrusive, about the same efficiency but unlike wind turbines, potentially able to reduce in cost with Moore’s Law. Initial cost would be similar (the costings I mention are based just on their sample prices, which obviously are usually far higher than finished large scale production), so still nowhere near as good as using shale gas, but it could be. Even then, we’d still need backup generation for when the wind isn’t blowing.

Conventional wind energy harvesting uses turbines on a grand scale, connected to a central motor. The whole thing needs heavy engineering, complex control systems and expensive and scarce materials such as neodymium for the motors. It is possible to build a system that is far more elegant, resource-efficient and less intrusive. Perhaps even much cheaper.

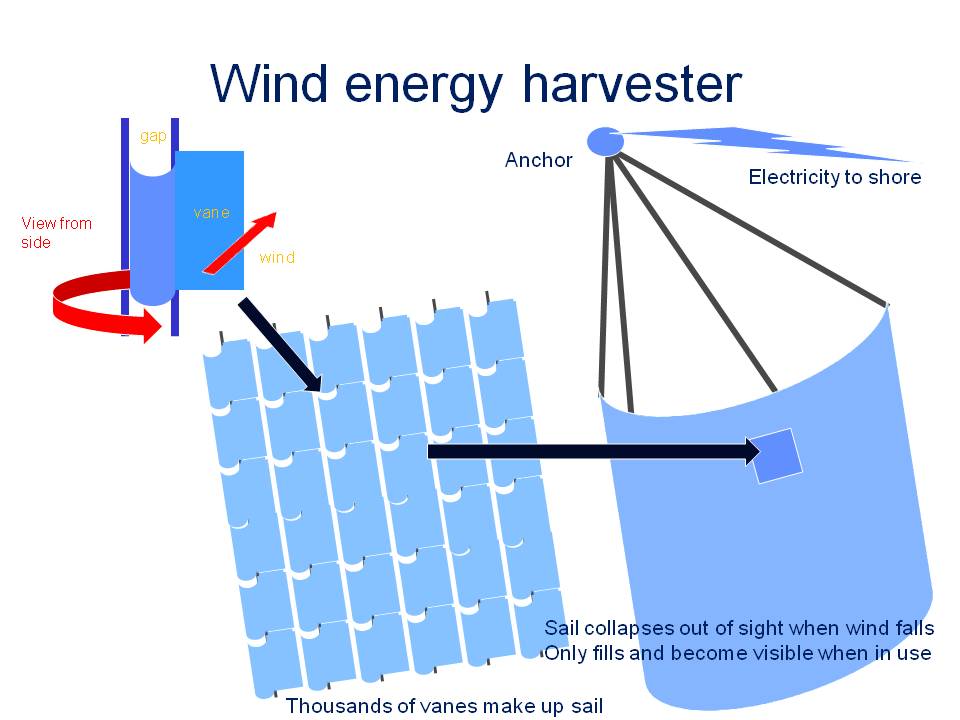

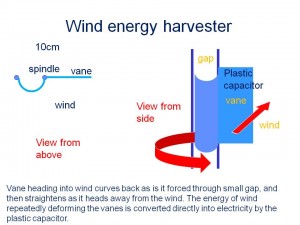

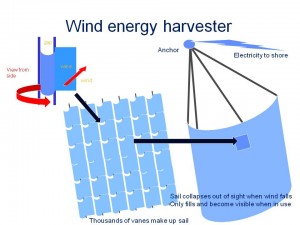

Some time ago a Danish company Danfoss, invented plastic capacitors, that generate electrical energy directly when they are bent. Wind pressure could be used to bend small vanes made of this material by pushing it around a spindle. As it rotates, one side goes through extended, the other side is forced to bend on the way back through the gap. By repeated bending and extending every time it rotates, each vane would generate electricity from the wind. These could be arranged in long strings, and many strings made up into a large sail.

The sail would be tethered to an anchor using ropes, and when the wind blows, it would fill up, the vanes would rotate, and energy would be harvested, with no need for a central motor or any heavy engineering. When the wind dies down, the sail would collapse so that it is less visible. Because the vanes individually would be small, just 5-10 centimetres across, no motion would be visible from any distance away, so they would not be as distracting as conventional turbines. Nor would they kill birds. Plastic capacitor sail generators would therefore have a few advantages over conventional approaches.

The disadvantage is that at the moment the material is fairly expensive, but there are excellent prospects for large cost reductions, and these could make it a far cheaper, as well as a greener, way of harvesting wind power.

Regardless of the specific method of conversion of atmospheric kinetic energy into electrical potential, the iron laws remain: “The amount of energy produced will be proportional to the cube power of wind speed,” “the most precisely designed turbines possible can extract no more than 56% of the kinetic energy in the wind,” and power produced will be in proportion to the square of turbine blade length.” In most locations where wind power is feasible, wind speeds increase at greater heights above the surface. The cube power law argues that small increases in wind speed yield large increases in power. Since the wind speeds are higher at greater heights the turbines are mounted atop tall towers, which also allows for larger blade diameter. Power increases with the square of blade length. Present wind turbines seem near ideal examples of form following function. The best executions extract about 90% of theoretical maxims. In most instances it wouldn’t make much sense to spend more money on the apparatus with a view to recover some percentage of the remaining 10%. So alternatives to wind turbines must justify themselves on the basis of lower overall costs with the frank acknowledgement that present designs are 90% as good as anything can ever be.

I’m not a general supporter of wind power, I don’t like the aesthetic appearance, the noise is a nuisance, and in locations where average wind speeds are below 18 miles per hour, overall costs of power production are higher than steam plants. I doubt the cost and service factor figures I’ve seen on the large off-shore wind farms in Denmark, but if they are valid, the proposition of pumped power storage in Norway’s several hydropower reservoirs makes economic sense. Norway needs the power and there is no practical way to expand the reservoirs. The hydropower plant capacities cannot be realized with available natural watershed flow rates. So if Danish wind turbines can keep Norway’s hydropower reservoirs full, it’s a win for both the Danes and the Norwegians.

Promoters and producers of wind power seem rarely objectively honest in their disclosures about cost/performance. A large wind turbine might claim a nameplate capacity of 3-MW, but when you check the fine print you learn the 3-MW is produced at a wind speed of 28 mph. But the turbine will likely be installed at a location where average wind speed is 15-17 mph. So in the most probable actual application the turbine would produce only 22% of nameplate rating, 0.67-MW. There is a huge difference in the economics of a power plant that costs $1,000 kW and one that costs $4,500 kW. One might as well consult an aluminum siding salesman as to likely service factor.

As always,insightful comments. What is your initial impression of what Ian Pearson has proposed?

Just doesn’t look competitive with large wind turbines. For over a hundred years, many really smart people have been working on how to best make electricity out of wind. The whole world has finally settled on the basic large diameter wind turbine design. That’s because not one of the thousands of smart guys that have worked on the problem has been able to come up with anything better. That doesn’t mean it’s impossible, just extremely unlikely. As I can understand the concept as presented it won’t produce as much power per unit of cost as the tried and proven turbines.

Keep in mind that the best wind turbines are a good idea only in the few areas that have favorable wind conditions. The areas with most favorable wind conditions tend to be remote from markets for the power. A couple of years back, T. Boone Pickins, the multi-billionaire Texas oil tycoon, went crazy on wind power and invested heavily in windy sites in the Texas Panhandle, and then figured out he would be able to produce a lot of power at competitive rates, but he would net lose money if he had to build the transmission system to move the power to major markets. So he invited the State and public utility companies to pay for the transmission system. The state and utility companies wisely said, “No thanks, we will build steam plants closer to markets. We will comply with federal renewable source mandates by locating wind farms only where the markets are not too distant, or where the transmission system already exists. The whole Texas Panhandle program turned into a huge boondoggle that cost T. Boone about a billion,

I’m about 99.9% sure nothing will ever significantly improve over the cost/performance of the present generation of large wind turbines, which for the most part are not cost competitive with steam power (It’s mostly a matter of average wind speed and nearby markets to take the intermittent power. The Danish/Norwegian pumped storage scheme is near ideal, but rare.). It’s hard to know whose cost figures to trust, but I have a reasonably credible MIT Grad acquaintance that is an active principal in the big West Texas wind farms. He grudgingly confesses his company is presently producing wind power electricity at true costs of about $0.08 kWh. Steam plants routinely generate power for less than half that.

To be fair, one should again notice that wind speed is a major factor, and that wind speed is a function of height. Ian’s scheme seems in essence to be a giant kite that uses some unique and imprecisely defined flex capacitor system for generating the power. In principle the “power kite” might be deployed in high winds at thousands of feet altitude, which might compensate for other inefficiencies in the system. Just looks like it would take a lot of money to construct and test a working prototype to prove it’s not such a good idea.

[…] here: Wind Turbines are Obtrusive – A Proposed Wind Harvester Alternative ← LAKE ERIE OFFSHORE #WIND #TURBINES: LEEDCo AWARDED […]