November 4, 2016 – Carbonate fuel cells are to be used to capture carbon dioxide (CO2) from a natural gas and coal-fired power generation facility located near Mobile, Alabama. Back in 2013, Kevin Bullis wrote an article in MIT Technology Review where he described using fuel cells to both generate electricity and selectively remove CO2 from exhaust gases at fossil-fuel burning power plants. The captured CO2 could then be stored underground while the fuel cells would produce power to offset the cost of implementation. The drawback was the cost of the electricity which would be as much as one-third higher.

Well now Southern Company, a subsidiary of Alabama Power, will play host to a FuelCell Energy, Inc., and ExxonMobil test pilot project at the James M. Barry Electric Generating Station, a 2.7 Gigawatt mixed-use coal and gas-fired power plant located near Mobile.

How does the technology work?

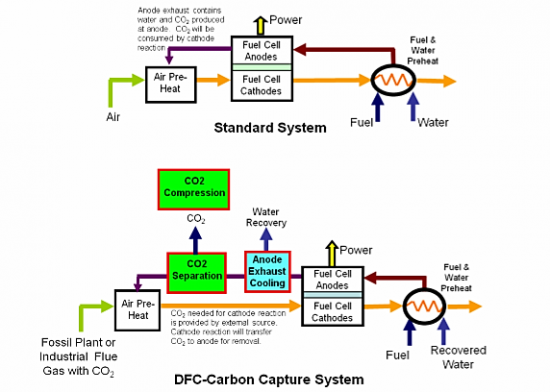

The technology, a DFC3000 fuel cell power plant consists of two modules each with four fuel-cell stacks, eight in total. Each fuel cell stack generates 350 kilowatts. A side effect of the electrochemical reaction between carbonate ions and the electrolyte is that CO2 introduced through an air inlet gets converted to carbonate ions, transfers through the electrolyte to the electrode and then converts back to CO2. This gives the DFC stack the ability to act as a carbon purification membrane without the need for additional technology. In a closed system the DFC stack recycles the CO2 continuously. But when put next to a thermal-power plant emitting CO2 it passes the gas through the fuel cell and then captures it when it has completed the transformation from gas to ions and back to gas again.

The schematic below shows two configurations for the DFC technology: as a standalone seen at the top, and beneath, as a carbon capture system when joined to a thermal-power generator spewing CO2.

Two additional benefits to the technology:

- In separating CO2 the cell produces water as a byproduct. Since many installations where a DFC can be deployed are significant water consumers the recovered liquid lowers freshwater demand.

- It also filters nitrous oxide from the flue gas when passing through the stack. Nitrous oxide is a potent greenhouse gas and a contributor to ground level ozone.

The typical transfer rate of a 2.8 Megawatt DFC3000 in normal operations processes 3,200 kilograms (7,000 pounds) of CO2 per hour with a carbon capture rate of 2,300 kilograms (over 5,000 pounds or 2.5 tons) per hour.

Seen in the image below the footprint requirement is small which makes this type of technology suitable for use as a standalone power generation technology that can supplement the transmission grid during peak period use. A number of utilities are looking at distributed power generation to supplement larger thermal plants.

The technology is scaleable and can be installed in modular increments. If the pilot is successful the next phase will include installation of eleven additional fuel cell stacks to generate 27.6 megawatts of power and capture 700 tons of CO2 while generating 648,000 kilowatt hours of ultra clean power daily.

Think about the implications if carbonate fuel cells were installed at all existing coal-fired power plants on the planet. We would decrease carbon emissions and produce a net power generation gain to boot. Makes you wonder why this project isn’t front and centre in the minds of utilities, fossil fuel energy companies and governments around the world.