May 26, 2017 – Besides Rocket Lab‘s successful launch of its 3D printed Electron rocket this week, the 3D printing or additive manufacturing world is undergoing all kinds of exciting developments. Here are just a few that caught my eye in the last few weeks.

Liquid Filament 3D Printing Creates Furniture in Minutes

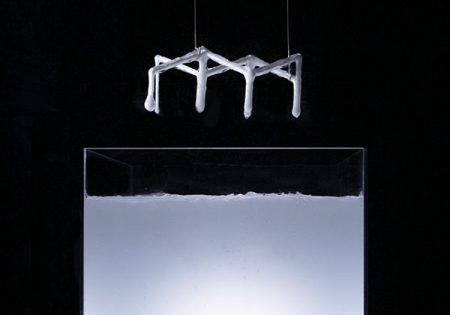

In a process called rapid liquid printing, MIT Self-Assembly Lab in collaboration with Steelcase has developed a gel suspension additive manufacturing technique capable of fast printing speeds. The technique produces precision large finished, durable products in minutes. This represents a real breakthrough in industrial-grade additive manufacturing.

Below you can see the Steelcase finished product, a 3D printed white coffee table. The table took 28 minutes to print. Conventional manufacturing processes, Steelcase estimates, would have taken up to 50 hours to create the same finished product.

Copper Inks Invented to 3D Print Electronics

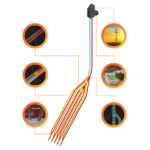

Optomec, an Arizona company, has developed metal 3D printing with copper inks to go along with its line of Optomec printers. The company has stated that the inks will “enable new classes of electronic devices helping to expand industrial use of 3D printed electronics.”

The company has developed a proprietary technology, Aerosol Jet, which allows direct printing onto 2D and 3D substrates. The metal inks are suspended in an aerosol mist. Prior to Optomec’s invention, copper was considered a very difficult material for use in additive manufacturing. The challenge was creating a stable ink with a medium that is difficult to melt.

Optomec also is working with copper-nickel alloy, gold, platinum, silver and aluminum. The inks will be used to 3D print circuit boards and more complex electronics. Currently, Optomec printers make smartphone antennas and replacement metal components for use in the aircraft industry.

The Aerosol Jet technology can use a wide range of inks including thick film pastes, epoxy, polymers and now metal inks. Printing can be applied to substrates made from polyester, polyamide, glass, ceramic, metals and even biomaterials.

3D Printing Metal Parts Now a Reality

Desktop Metal is an MIT spinoff located in Burlington, Massachusetts. Four material scientists from MIT created the company which recently received $100 million U.S. from venture capital and new venture divisions of Alphabet, BMW, and General Electric. So what has got these investors excited?

So what has got these investors excited? Mass-produced printed metal parts.

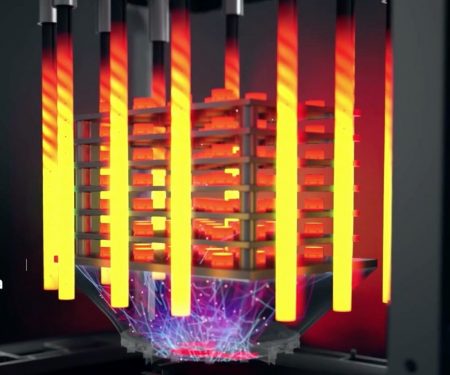

Desktop Metal is in the process of completing the design of the first metal 3D printing system that delivers metal parts using Single Pass Jetting (SPJ), a process that manufactures complex metal parts at high rates of speed using a bi-directional printhead with 32,000 jets that builds a product in “a matter of minutes instead of hours.” Unlike laser-based processes, there is no welding of components to finish a completed part. The single-pass process produces a finished product every time.

The new company describes its additive manufacturing technology as “the fastest way to manufacture complex metal parts” and claims its processes will produce parts at costs “up to 20x lower than today’s metal 3D printing systems…..competitive with traditional manufacturing processes.” The big question, will manufacturers readily buy into additive manufacturing to replace existing processes? It’s a wait and see with the delivery date for the first DM Production System sometime in 2018. You can reserve one of the printers for $5,000 U.S.

Dentists Into 3D Printing

In 2016 sales of dental 3D printers grew 75%. High-speed 3D printers are moving into dental offices at an unprecedented rate to provide custom prosthetics, orthodontic appliances, and other dental parts. It is one of the most disruptive changes to happen to dentistry and dental labs. For the latter, it may mean their demise.

One 3D printing company, EnvisionTEC, produces a line of printers that allow dentists to print bridges, crowns, models, surgical drill guides, night guards and more. The technology works with CAD and other design software such as 3Shape and Ental Wings to take digital images and then render precision designs. The printers use a wide range of inks to produce high-quality, low-cost finished dental appliances with an accuracy of fit down to 10 microns.

One of EnvisionTEC’s printers, the VIDA, seen below, is sold to dental practices or small dental labs. It prints dental and orthodontic models, surgical guides, partial rameworks and bite guards. More advanced models of this printer are used to produce crowns and bridges.

Seen below a dental and bridge printed using EnvisionTEC 3D printing.