How about bringing home your own 3D printer? Or how about building your home with a 3D printer? Two new 3D stories caught my eye this week. The first involves a couple of MIT mechanical engineering students who have built a 3D printer that fits into a suitcase and can be taken anywhere. The second comes from a University of Southern California professor who sees 3D printers as capable of building a house in 24 hours, a seriously disruptive innovation for the construction industry.

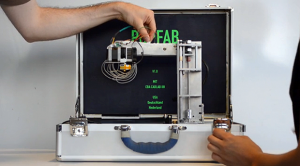

A 3D Printer To Go

Called the PopFab, Ilan Moyer and Nadya Peek at MIT have built a 3D printer in a suitcase. The printer features a computer-controlled multi-tool print head capable of handling a variety of materials and a motion-controlled platform upon which to assemble finished 3D-printed objects. Attach a CAD software package to the device, design something, feed the printer with the appropriate material, and hit print. The printer has the functional capability to operate as a computer numerical control milling machine, a programmable drawing tool, or vinyl cutter. The designers promise much more in the near future but for CAD users PopFab sounds like a perfect fit.

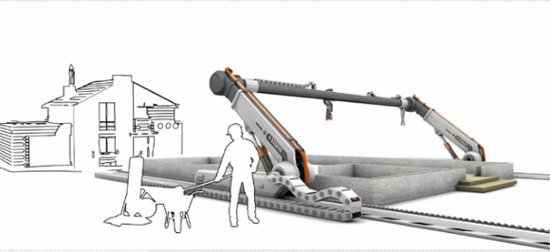

A 3D Printed House

Behrokh Khoshnevis, a professor at USC’s Viterbi School of Engineering, has developed 3D printing technology that uses concrete to build houses. The technology is called contour crafting. This 3D printer doesn’t fit in a suitcase. It is as large format as you can imagine, capable of fabricating walls by extruding materials in layers, taking instruction from computer-aided-design and manufacturing software. A 185 square meter (2,000 square foot) home using contour crafting technology can be built in 24 hours. This includes inserting rebar (reinforcing steel), plumbing and electrical wiring in the manufacturing process.

Contour crafting can use any construction material that can be extruded through its 3D printer heads. That means builders using local rather than transported materials on the construction site. The 3D print technology can be fed numerous designs so that no two houses appear the same. Even the colour and finish of interior and exterior walls can be applied through this printing process.

For the many informal settlements and shantytowns that have come about as mass migration alters urban centres in the Developing World, contour crafting technology appears to be a way to provide housing and services for new urban immigrants at affordable costs. And ultimately contour crafting presents an ideal tool for the manufacturing of off-world buildings such as on the Moon and Mars.