Recently in a blog focused on the evolution of materials for automobiles I wrote about the future of shape memory polymers, self-healing nanoparticle-based plastics that return to their original shape after being dented or dinged. Well it seems the future is getting closer to the present.

At the March 2012 meeting of the 243rd National Meeting & Exposition of the American Chemical Society (ACS), Professor Marek Urban from the University of Southern Mississippi reported that his team of researchers had developed plastics, that when scratched or cracked, visibly change colour at the point of the defect. And when the damage is exposed to visible light, heat or acid respond by “healing” and restoring themselves to their original colour. The plastics can repeatedly respond this way doing self-repair many times.

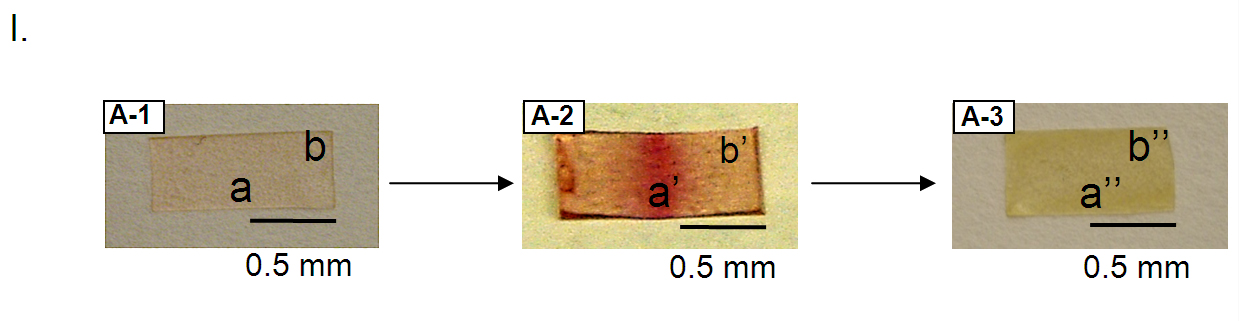

What makes this possible? The self-healing plastic contains small molecular links or bridges that span the long chemical chains within the material. When the plastic is scratched or cracked, those links break, changing shape. The change in shape alters the colour appearance of the plastic turning it red. A sample of this process is seen in the picture below.

- Plastics developed by the University of Southern Mississippi turn red where damaged and “heal” after exposure to light, heat or acid. The plastic on the left (A-1) is the original material. The middle image (A-2) displays damage . The self-healed plastic (A-3) is restored after exposure to light. Source: Professor Marek Urban

This new plastic is water-based and contains no toxic chemicals making it even more attractive. You can imagine the wide range of industrial uses this kind of material would have because it visibly warns the manufacturer or user of damage and requires easily accessible processes for repair.

For the automobile industry plastics like this would make it easy to deal with the repair of incidental scratches to an automobile body. Just exposure to sunlight would repair the damage. In fact, the material could be used in any mission-critical structure where any damage to materials would immediately be seen and repaired by applying light, heat or acid to the defective part.

Increasingly we rely on plastics in manufacturing. Plastics have replaced steel, aluminum, glass, paper and other traditional materials. With this technology plastics will become even more appealing as the material of choice in manufacturing.