January 12, 2017 – With the approval of the Trans-Mountain pipeline by both British Columbia and Canada’s federal governments, the oil sands aren’t going away in the near future. The environmental challenges that oil sands operations present are much larger than the carbon emitted into the atmosphere through the production process as well as the ultimate burning of the end products by consumers. The large tailing ponds remain the most visible environmental insult.

What can be done with them?

That’s what MGX Minerals Inc., a Vancouver-based company, is attempting to tackle. Is there value in what oil sands operations produce in waste?

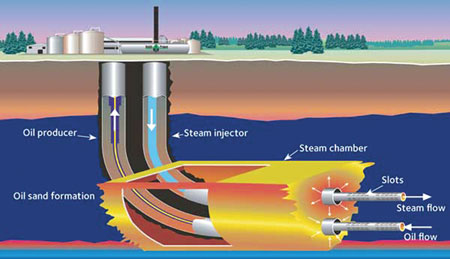

The tailing ponds may have to wait for awhile. The ponds are largely the end result of older oil sands extraction processes. Newer methods such as steam-assisted gravity drainage are showing in the wastewater brine produced a potential economic benefit.

In a January 3, 2017 announcement, MGX reported it was successfully extracting lithium from oil wastewater at rates of between 100 to 140 milligrams per liter in a series of pilot test projects using its patent pending processes. Lithium isn’t the only product of the oil wastewater. Described as “the first of its kind,” it turns what is referred to as “blowdown wastewater” into a revenue generator.

MGX is partnering with PurLucid Treatment Solutions to create a commercial operation to help oil sands producers by introducing more “environmentally-friendly disposal options as well as recover valuable minerals.” During the recovery process 21% of the total lithium contained in the wastewater brine can be converted into lithium carbonate. The other valuable minerals that could conceivably prove to have commercial value include sodium, calcium, potassium, bromine, magnesium and boron. During the process 99.97% of the hydrocarbons were reduced to allow the oil sands operators to reuse the water in the steam-assisted gravity drainage operations (see graphic below).

In the past wastewater brine containing dissolved minerals used evaporative processes to extract lithium and other valuable substances. But the technology MGX has developed accomplishes in a day what previous methods take as much as 18 months to produce. And the extraction yield at 40% currently makes the technology commercially viable. States MGX President and CEO, Jared Lazerson, “I think we’ll be at 60% recovery fairly quickly.” Lazerson continues, “We focused on….developing an industrial process that would combine the evaporation and processing with very high recoveries….Nobody else has done this before.”

Global demand for lithium continues to grow as sustainable technology such as electric vehicles and battery storage become more commonplace in a world seeking low carbon alternatives to fossil fuel energy. It is somewhat ironic that the process MGX created comes from fossil fuel operations.

[…] MGX and PurLucid Treatment Solutions create lithium extraction technology that recovers it from oil sands steam-assisted gravity drainage. […]