July 13, 2014 – As shipwrecks go the Costa Concordia has proven to be the media sensation of the 21st century. We have seen more footage of this disaster, have read more print copy, and have been eyewitness to the salvage operation to right the ship so that it can be towed away.

Tomorrow begins the final operation to remove the 290 meter (950 foot) vessel, 114,500 tons, more than twice the size and weight of the Titanic, from the rocks upon which it settled on January 13, 2012. Of the more than 4,000 passengers on board, 32 died. Nothing can be done for those who lost their lives but at least the ship can be removed from the watery grave where they lost their lives.

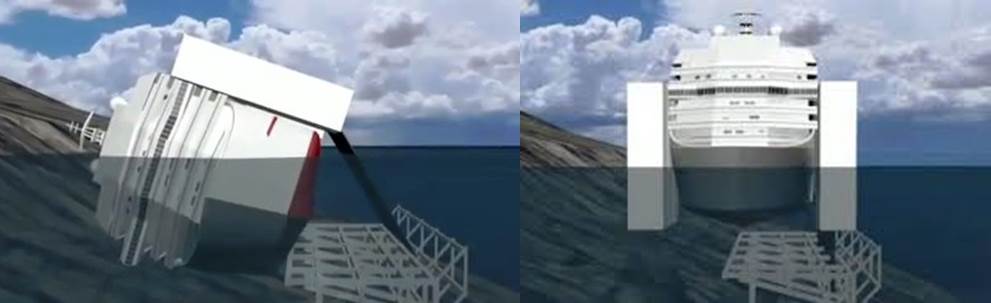

The Costa Concordia salvage operation has been ongoing for more than two years and has involved a parbuckling process on a scale never conceived before. It includes building a platform near and under the ship, attaching flotation tanks to the ship sides, righting the vessel to a vertical position, and refloating it off the rocks before towing it away.

All of this technology had to be installed on site and custom designed. Some had been applied to previous shipwrecks but much of the technology had to be developed from scratch. The company chosen to accomplish this enormous task is Titan Salvage, an American leader in salvage operations.

Before Titan could begin its work the remaining fuel on board the Costa Concordia had to be removed with bunker fuel leaks contained by booms while skimmers removed as much of the fuel as possible from the vicinity of the wreck. Titan then proposed a multi-step operation involving:

- Stabilizing the ship by building a subsea platform upon which to rest the ship during the righting operation which would involved securing caissons to one side of the ship which would then be filled with water while cranes would winch the vessel into an upright position.

- Once upright applying similar caissons to the other side of the ship which would also be water filled. Then to refloat the vessel the caissons on both sides would be emptied of their water and pumped full of air.

- Then towing the vessel once afloat to an Italian port, in this case Genoa, where it could be scrapped.

The operation was designed to minimize the environmental impact on the wreck site, the Island of Giglio. Even the water pumped from the caissons during refloating would be filtered to ensure no contaminants entered the local marine environment.

In the past we would have seen a salvage operation done on site, cutting up the ship where it lay, and possibly leaving subsurface parts where they lay. The threat of contamination to the local environment would have been significant.

But in the 21st century we have technology that allowed us to do what seems to be the impossible. We could create an accurate site map of the wreck within millimeters using sophisticated underwater scanning technologies. We could simulate the planning of the salvage operation and test various scenarios to perfect the process. We could constantly monitor the environment beginning with a baseline survey shortly after the ship tore a 70 meter (230 foot) long hole in its hull before it keeled over on its side and settled on a rock shelf. We could place monitoring sensors in the environment to do continuous sampling of ecotoxicological, hydromorphological and biological data through the entire water column and sea floor in the vicinity of the wreck. And then we could execute on the operation to the point where we have almost seen a successful completion of what seemed a near impossible task.

All of this had to be done while the ship rested on a precarious ridge of rocks while subject to the changing weather, waves and tidal action of the Mediterranean Sea for a period of more than two years.

Could we have accomplished such an operation in the 20th century? Not a chance. Let’s hope we don’t have to be so creative with 21st century technology for a future wreck.