April 2, 2014 – While traveling south to Florida this year my wife and I reached Southern Kentucky where highway signs told us we were entering a fog zone that extended all the way into Northern Tennessee. This was no ordinary fog. It was pulp and paper fog, produced by the many mills that dot the mountainous and forested areas of these states.

For the past century and a half, humanity has been manufacturing paper products from trees. It wasn’t always the case. The Egyptians made paper from papyrus, a reed that grew on the banks of the Nile River. The Romans made paper from cloth rags. If you watched the Amazing Race last week you saw paper being made from elephant dung. In fact paper has been made from all kinds of materials over the years.

But in the mid-19th century the modern pulp and paper industry established itself and we have been dealing with the consequences ever since. What we gained from using trees was an industrial process that made paper very affordable. What we also gained was paper pollution to air, water and land.

Some basic industry facts about pulp and paper:

- By 2020 the world will produce 500 billion tons of paper products annually.

- It consumes 4 billion or 35% of all harvested trees on the planet each year.

- It is the fourth largest industrial user of energy on the planet.

- It consumes more freshwater per ton than any other manufactured product.

- 40% of the paper produced for business each year ends up in landfill.

- It is the third largest industrial polluter on the planet, a prime greenhouse gas emitter of CO2 with smaller amounts of CH4 and N2O.

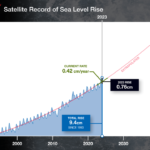

In the U.S. alone the industry emits 113 million metric tons of CO2 per year not including indirect emissions from its electricity sources and secondary manufacturing operations including transportation. Those amount to 34.3 million metric tons per year. In Asia 2006 estimates of CO2 emissions, based on figures from the Rainforest Action Network and the Japanese Tropical Forest Network, amounted to 86 million metric tons annually.

The industry today in North America largely gets its product from plantation forests. Every tree harvested gets replaced by a new planting. But in other parts of the world old growth forests are being turned into wood pulp leading to deforestation. In addition the pulp and paper production process introduces bleaching agents like chlorine into the environment through wastewater. That along with inks, dyes and polymers, all found in paper production, contributes to water pollution downstream from mills. Chlorine today is being replaced or minimized by kraft paper mills. There remains, however, a residual problem with chlorinated organic compounds including dioxins, considered highly toxic and carcinogenic.

But the air pollution is another issue. You can’t help noticing the smell of rotten eggs when you are within a 30 to 50 kilometer perimeter of a pulp and paper mill. When my wife and I on our honeymoon drove across Canada, you could smell the mills of Dryden, Ontario a good 50 kilometers or more before we got to the city. When traveling through Tennessee and Georgia, the smell of sulfur suddenly permeates the air. That’s because the industry uses a sulfite process in making wood pulp which leads to the release of SO2 into the air. In 2006 in Canada the industry was responsible for putting 60,000 tons of SO2 into the atmosphere. SO2 is the primary cause of acid rain.

So we know that the industry we hatched in the mid-19th century if left to continue without some reinvention will not help us to globally reduce the human carbon footprint. What will, however, is the finding of new sources and processes for making affordable, quality paper and paper products.

Enter Woody Harrelson, of Cheers and True Detective fame and Jeff Golman, an eco-minded entrepreneur, with a paper made from wheat straw. This partnership, and their company Prairie Paper, aims to turn the industry upside down using left over wheat stubble from farms into the raw material for paper production. Their product is Step Forward Paper and in 2012 office supplier, Staples, began selling it in its 2,000 stores worldwide as well as online through its web store.

On its website, Prairie Paper describes how paper made from wheat is contributing to reducing our human carbon footprint. The sales to date have saved us from putting 6.1 million tons of CO2 into the atmosphere. In addition the trees saved (11,081 so far) equals a forest as large as 20 football fields. And they are just getting started. If your company chooses to use their product it can calculate how many trees it will save by month, and the associated carbon footprint reduction using a handy online calculator.

Can wheat stubble replace forests in paper production? There are challenges. For example, the raw material issue. To get the same density from wheat stubble you need between 5 and 20 times the product to get the same density in product. That means your harvest area is as much as 40 times larger than a harvestable forest. With lower density it means your transportation to the processing facility costs more. The additional problem occurs because of the seasonality of wheat stubble which only becomes available once per year, whereas forests can be harvested year round. And finally, farmers who use the wheat residue to maintain the soil after harvest, or who burn it to render the carbon and other residue so that it can fertilize the fields, may not want to part with the stubble regardless of what the paper processor is willing to pay for the product.