Decarbonized oil, new distillation processes, hydrogen, and carbon sequestration stories have all been in the news recently. Let’s do a quick drill down on these stories.

Is Decarbonized Oil Real?

Canada’s new Prime Minister, Mark Carney, has included in the government’s goals the development of “decarbonized oil” projects. In previous roles, Carney has been an active environmentalist and has led business initiatives to address climate change. He was the United Nations’ climate change ambassador. That’s why the reference to decarbonized oil doesn’t sound genuine. It comes across as more of a marketing slogan and a gesture to Canada’s fossil fuel producers.

What does Carney mean? His decarbonized oil projects implement carbon reduction technologies during extraction, processing and transportation. In a news conference, Carney pointed to the example of the Pathways Alliance project. I have written several articles about Pathways and have watched how the oil sands operators talk the talk but seldom walk the walk.

Pathways is a proposed carbon capture and storage (CCS) network of pipelines intended to remove tens of millions of tons of carbon dioxide (CO2) from oil sands producers. The captured CO2 is to be transported to safe underground sites hundreds of kilometres away for permanent safe storage.

The members of Pathways believe, if the project is built, they would have the license to continue to grow their oil sands projects while they sequester the CO2. The International Energy Agency (IEA) disputes this claim, stating it is incompatible with mitigating climate change and achieving net-zero emissions by 2050.

Commenting on Carney’s decarbonized oil remarks, University of British Columbia climate scientist Simon Donner, co-chair of the federal Net Zero Advisory Body, stated, “There is no such thing as decarbonized oil and gas. Oil contains carbon. It is high school chemistry. The government is going to embarrass itself by using such industry and marketing speak.”

There are ways to lower the carbon intensity for each barrel of heavy oil produced from oil sands bitumen. Carbon intensity reduction, however, is not decarbonized oil.

Carney aspires for Canada to be an energy superpower that will produce both conventional and renewable forms of energy, but decarbonized oil, as he describes it, is anything but a climate change mitigation solution.

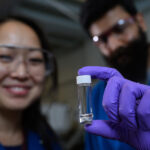

Researchers Develop New Materials For Processing Crude Oil

Researchers at the Massachusetts Institute of Technology (MIT) note that turning crude oil into gasoline, diesel and heating oil produces 6% of all global carbon emissions. That is because distilling crude, current methods require heat generated from burning fossil fuels.

MIT researchers have been looking at new technologies to lower emissions from oil refining operations. They have developed a membrane that efficiently separates the molecular components of crude without needing to heat it. The researchers claim this reduces the amount of energy needed for distillation by 90%.

Their discovery of a microporous polyimine membrane appears in the May 22, 2025, edition of the journal Science. The membrane is a modified version of one used in water desalination plants. It can be mass-produced.

Referring to the method for creating the membrane, Tae Hoon Lee, in MIT’s Department of Chemical Engineering, and the lead author of the paper state, “The main advantage of interfacial polymerization is it’s already a well-established method to prepare membranes for water purification, so you can imagine just adopting these chemistries into existing scale of manufacturing lines.”

Natural Hydrogen Reserves Identified

Finding natural hydrogen here on Earth has always been problematic. That’s because hydrogen is the lightest element in the periodic table and tends to bind with other elements.

On Earth, hydrogen binds with oxygen to make water (H2O). It also binds with carbon to form methane (CH4) and other hydrocarbons. It binds with nitrogen to make ammonia (NH3), with sulphur to make hydrogen sulphide (H2S), with chlorine to make hydrogen chloride (HCL), with fluorine to make hydrogen fluoride (HF), and it combines with metals such as Sodium (NaH), and Lithium (LiAIH4) to make metal hydrides.

Today, besides being a clean fuel, hydrogen is used to produce fertilizer and is seen as an alternative fuel for clean manufacturing and transportation in pursuit of a net-zero future. The problem is sourcing the gas. Most hydrogen is produced in fossil fuel distillation processes or by electrolyzers. The former produces gray hydrogen, which produces carbon emissions. The latter splits water to make green hydrogen if the electricity is sourced from renewables.

The latest discovery by scientists from Oxford University, Durham University and the University of Toronto provides a very different hydrogen source. It is in underground rock formations where natural hydrogen reservoirs accumulate. The discovery is described in the May 13, 2025, issue of the journal Nature Reviews: Earth & Environment.

How did the natural hydrogen reserves form? Earth’s Archaean crust developed between 4 and 2.5 billion years ago. Within both the continental and oceanic crusts, hydrogen has been accumulating from chemical interactions with minerals and water. How much? The researchers believe these natural hydrogen reservoirs contain enough of the gas to meet Earth’s energy needs for the next 170,000 years. That should be enough to keep the machinery going and the lights on without adding an ounce of carbon emissions to the atmosphere and ocean.

More Efficient Carbon Capture Technology Invented

It seems MIT’s dabbling with membranes isn’t just yielding breakthroughs for crude oil distillation processes. A nanofiltration membrane developed at the school is making carbon capture six times more efficient and 20% less expensive using commercially available materials.

Today, CO2 capture applies several different methods:

- Point source capture from power plants and manufacturing sites,

- Pre-combustion capture in new industrial plants,

- Oxy-fuel combustion in flue gas,

- Direct air capture (DAC).

DAC methods use solid or solution adsorbents to capture CO2. DAC’s cost per ton of captured CO2 currently is US$ 600. The new nanofiltration membrane brings that down to $450. The membrane isn’t limited to DAC. It can be used with point source capture as well and is non-toxic.

Kripa Varanasi, a professor in MIT’s Department of Mechanical Engineering and one of four who wrote the paper appearing in the May 20, 2025, edition of ACS Energy Letters, notes that the nanofilter can be further fine-tuned to bring the cost per captured ton to $200. At that price, it would make most carbon capture processes economically viable, particularly since industries are buying carbon credits exceeding $500 per ton today.