Batteries are heavy, and when used to power aircraft, as they expend energy, they don’t get lighter. Aviation-fueled aircraft do get lighter the longer they fly as their tanks drain.

The getting lighter extends the distance they can travel. A battery-powered airplane, however, remains the same weight throughout a flight before landing to recharge. Recharging can take several hours before the airplane can fly again. If you owned an airline, an electric battery-powered aircraft would produce an abysmal business model because the frequency of flights with passengers or freight on board is the key to being profitable.

Going the battery route, therefore, seems only to make sense with short-haul, smaller aircraft, a developing industry niche. Solutions exist to develop lighter batteries that don’t use a liquid oxidizer, which saves considerable weight. Air-breathing batteries that use lithium, zinc, potassium or sodium metals as the anode and a cathode fed by air represent a promising alternative. Another route to go is air-breathing fuel cells.

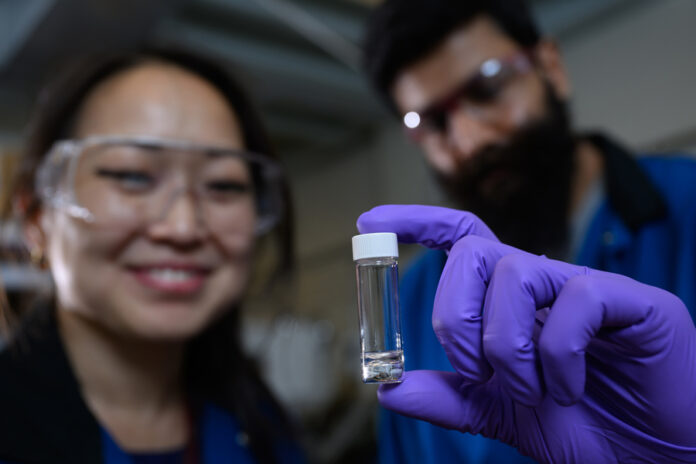

Researchers at the Massachusetts Institute of Technology (MIT) have not been working on a battery but rather a fuel cell that uses liquid sodium. It uses a solid ceramic layer as an interface between the sodium and an electrode exposed to air. This sodium-air fuel cell stores more than three times the energy per weight as the lithium-ion battery packs used in electric vehicles today.

The MIT team has produced two versions of cells. One uses a vertical design where liquid sodium flows down through a ceramic electrolyte to connect to a porous air electrode to generate an electrochemical reaction. The second design is horizontal with the liquid sodium positioned in a layer next to a porous air electrode. The horizontal design allows the fuel cells to be stacked in layers. They can be rolled in and out of an aircraft on a hand cart.

The research team described their invention in the May 27, 2025, edition of the journal Joule. Material Sciences Professor Yet-Ming Chiang, one of the 5 involved in the project, described the advantages of the design to MIT News, stating, “The threshold that you really need for realistic electric aviation is about 1,000 watt-hours per kilogram.” Compare that number to current lithium-ion batteries that top out at 300 watt-hours per kilogram.

The power limitations of lithium-ion, plus the weight of each battery pack, make using them impractical for flying transcontinental or trans-Atlantic routes. The MIT prototypes have been able to generate 1,500 watt-hours (Wh) per kilogram with the ambient air’s humidity precisely controlled. The result is a multilayered fuel cell stack that generates over 1,000 Wh per cell. Aircraft equipped with these fuel cells can fly 80% of the domestic routes in the United States while producing 30% less pollution.

As the sodium metal transforms through the electrochemical reaction, the cells produce sodium oxide (Na2O) that is passed into the exhaust stream. Three things are good about this.

- The cells produce no carbon dioxide (CO2) emissions.

- The Na2O, when it reacts with outside air, turns into sodium hydroxide (NaOH), which, when combined with the CO2, becomes sodium bicarbonate (NaHCO3), commonly called baking soda.

- NaHCO3 absorbed by ocean water becomes less acidic, countering the damaging effect of rising CO2 levels in the atmosphere, which, when absorbed by the seawater, produces carbonic acid.

Professor Chiang notes that using the MIT fuel cell would be far safer than lithium-ion batteries. Although liquid sodium is extremely reactive and can spontaneously ignite like lithium-based battery materials, the use of ambient air and the solid ceramic interface eliminates the danger of a runaway reaction.

Chiang states, “In this fuel cell, one side is just air, which is dilute and limited. So you don’t have two concentrated reactants right next to each other. If you’re pushing for really, really high energy density, you’d rather have a fuel cell than a battery for safety reasons.”

So, what’s the next stage for this MIT team in their fuel cell initiative? Commercialization is in the offing with the inventors forming a company called Propel Aero. Although the website is no more than a home page at present, the team plans to produce brick-sized cells to power a large drone within the next year. Each fuel cell would contain a refillable cartridge containing liquid sodium metal.

Before the advent of unleaded gasoline, the U.S. produced 200,000 tons of sodium metal annually. Sodium metal is produced from salt. Salt melts when it reaches 98 Celsius (208.4 Fahrenheit), turning into a liquid. There is no lack of salt around, unlike more rare sources of liquid metals like lithium. It shouldn’t, therefore, be a difficult step to overcome in getting back to producing sodium metal.