December 20, 2013 – University of Twente in the Netherlands, under its Green Energy Initiative, has designed a new superconducting cable system for fusion reactors. This new cable system is temperature tolerant beyond any previous designs and has vastly increased the likelihood that we will see operational nuclear fusion prototypes by 2020.

The Twente-developed technology uses interweaving to withstand the super cold temperatures needed for superconductivity to maintain the magnetic fields and the fusion reaction. Those magnetic field coils represent one-third of the cost of a fusion reactor. In the past the cables have been the Achilles heel. They couldn’t withstand the 40 to 60,000 charge cycles needed to make fusion reactors economically viable. The new design, however, has the ability to extend fusion reactor operational life to meet or even exceed these limits and thus dramatically lower costs.

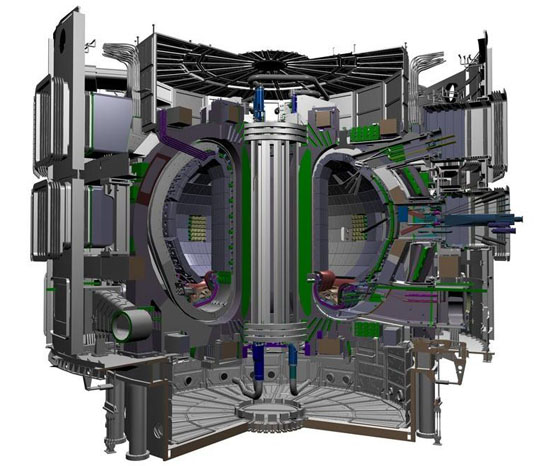

What’s involved in a fusion reactor? The fusion chamber contains super-heated 150-million Celsius degrees plasma which is held together by a strong magnetic field. The field is maintained at a temperature far below that, -269 Celsius degrees. This super-cold temperatures creates superconductivity, that is, zero-resistance within the cables that generate the magnetic field. Liquid helium is the refrigerant. Although rare on Earth helium appears to be abundant on the Moon and that’s why there is interest in lunar mining of it, but that’s another story.

As you can imagine the juxtaposition of heated plasma and near absolute zero temperatures can play havoc with any wiring. Rapid changes in the magnetic field as well leads to excess heat within the cable system itself/ That causes superconductivity and fusion to stop. Interweaving the wires, however, prevents this from happening.

Each superconducting cable contains 864 individual wires, each 0.8 millimeters (0.03 inches) thick. This design reduces current eddies and any heat build up that could impact superconductivity. The cable system in total stands 13 meters (42 feet) high and consists of six coils containing the interwoven wires which you can see in the picture below. The material used consists of a pair of wires made from niobium-tin and one from copper. The latter provides greater heat resistance to maintain a superconducting state.

The new cables will be incorporated into the multinational-financed nuclear fusion reactor project, ITER, under construction in France, expected to become operational by 2020. Both China and South Korea, each with independent fusion reactor programs, have also expressed interested in incorporating the Twente design which will probably become an international standard.

Though this I’d a positive step, we still haven’t gotten a consistent break even on energy in to energy out. There is still a lot of research to get through before non-stellar fusion becomes viable for energy production.

Hi Steve, The impediment to a practical, economically viable fusion reactor has always been about energy in, energy out. What the University of Twente researchers have accomplished is creating conditions where the plasma containment can be maintained long enough to provide that net energy return. So the conditions for better than break even are almost met. With South Korea and China on a fast track to develop fusion my bet is they will be first to success well before ITER.