Once again, welcome Jane Marsh to 21st Century Tech Blog. In her posting today Jane describes a Lithium-ion (Li-ion) battery that is not currently being used by Tesla and other electric vehicle (EV) manufacturers.

The first electric horseless carriage appeared in 1828. Note, nobody decided to shorten the name to car until the 20th century. Those first EVs didn’t compete with horse-drawn transportation until the very end of the 19th century with a few thousand in existence by then. However, the EV as successor to the horse was short-lived because of Henry Ford’s standardization and promotion of the internal combustion engine running on gasoline. Ford mass-produced his Model Ts and EVs soon disappeared. That is until recently when climate change provided a compelling reason to reconsider electrified personal transportation as a way to mitigate atmospheric warming caused by carbon and other greenhouse gas emissions.

Before Tesla made the Li-ion battery pack the gold standard of current EVs, manufacturers experimented with Lead-Acid (invented in 1859), Nickel-Iron and Nickel-Cadmium (both appearing in 1899) and Nickel-Metal Hydride (invented in 1991). But the first Li-ion battery appeared in 1985 and soon achieved dominance as today’s battery of choice in portable devices and EVs. But Li-ion isn’t a perfect solution and I will let Jane tell you why.

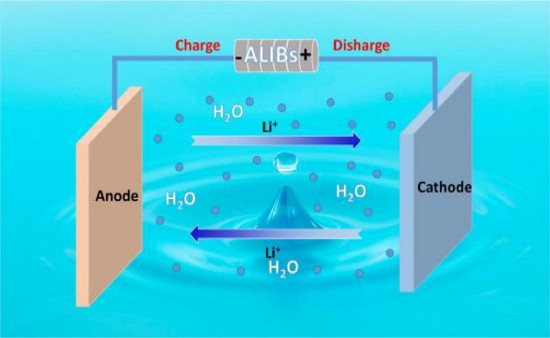

An Aqueous Li-ion Battery

Safety and environmental concerns abound regarding Li-ion batteries. What are the technology’s challenges?

Li-ion batteries have two major failings.

- Degradation over time – they begin to lose recharge capacity more frequently if the ambient environment is too warm or cold.

- Battery failure – where the interface that separates the electrolyte from the cathode and anode leaks forming dendrites and eventually causing overheating.

No doubt you have seen pictures of laptop computers going up in smoke, and an occasional Tesla catching on fire. To counter these risks, current Li-ion battery packs feature battery management systems designed to protect them from overheating through thousands of charge-discharge cycles that can lead to thermal runaway where battery temperatures reach 500 Celsius (932 Fahrenheit) degrees.

But an aqueous Li-on battery eliminates the hazard of overheating and could change the EV world providing faster charging, and a safer environment for users. So how do they work and why aren’t they already the gold standard for EVs today?

After numerous unexpected fires, Li-ion technology needs a rethink. What better way to counteract fire than with water? An aqueous Li-ion battery removes flammable organic solvents in existing battery technology and replaces them with aqueous saline solutions for managing current flow.

But water-based electrolytes in aqueous lithium-ion batteries, although resistant to fire, are not immune to a risk of explosion. This is because the sealing structure in current Li-ion technology limits heat dissipation and pressure within the cells. Some are experimenting with Li-ion open configurations using aqueous electrolytes and aluminum-oxide-coated anodes to minimize the explosion risk.

Experiments with aqueous Li-ion batteries to address extreme weather incidents are also being researched because of the growing threat of a more volatile climate in the near future.

Are There Other Drawbacks to Aqueous Li-ion Batteries?

Generating power from a saline solution relies on an electrochemical sliver of opportunity known as the potential window of stability. This window is short and the most significant drawback to the technology’s mass adoption. Until remedied, it’s unlikely to replace current Li-ion batteries.

Tinkering with Li-ion technology, some have suggested replacing flammable solvents entirely or using more eco-conscious, plentiful metals like magnesium. But the latter can warp in aqueous environments, reducing efficacy. Generally, each solution to combat current Li-ion issues has drawbacks.

In the meantime, aqueous Li-ion technology is finding niche uses where limited resilience and longevity are less of an issue such as for the military.

Aqueous Li-ion Recyclability

If the fire and explosion issues aren’t enough to give battery developers reasons to look at other improvements, recyclability to reduce pollution should be high on the list. An aqueous Li-ion battery eliminates the use of toxic materials that require invasive and destructive methods to mine and transform for manufacturing. The processes are currently so complex and expensive that recycling Li-ion batteries is largely not done by companies that use them in EVs and other devices. Only recently have specialized Li-ion recyclers emerged like Li-Cycle, a Canadian-based company that announced the building of a new European recycling hub a few days ago. Changing the technology to aqueous Li-ion would make the job of recycling companies and the reuse of the recovered materials far more attractive.

Will Aqueous Batteries Meet EV Expectations?

The EV industry is continuing to innovate Li-ion technology, looking for other ways to cool down these battery packs. Aqueous batteries appear to be an attractive option considering the need to address performance, safety, and sustainability. With the predicted number of Li-ion batteries expected to reach end-of-life by 2025, which amounts to around 3.4 million units, innovation is seen as a continuous priority.

At the same time, EV manufacturers are looking at ways to protect their cars from Li-ion issues by looking at improving ventilation and changing vehicle coatings to make them more fire and explosion resistant.

Electroplating or powder coating of EV parts can be used to create higher durability against fire, UV radiation and impact. The coatings manage vehicle temperature by maximizing organic chemical traits, like phosphorus ferromagnetism or silver’s heat conductivity. Aqueous battery replacements could add to the margin of safety.

Improved battery ventilation would reduce thermal runaway, a condition we previously described. Today’s EVs have minimal space to contain or manage their volatile components and materials. But these substances, cause consequences from slight smoking to alarming explosions. That’s why work is being done on design changes to improve airflow.