June 8, 2018 – Yesterday, Carbon Engineering, a Canadian carbon capture technology pioneer, published its latest findings in the peer-reviewed journal, Joule, describing its experience at its pilot plant in Squamish, British Columbia. When I first described this company and its breakthrough technology back in 2015, it had taken it 6 years to perfect the technology. At that time one of its biggest boosters was Bill Gates of Microsoft fame.

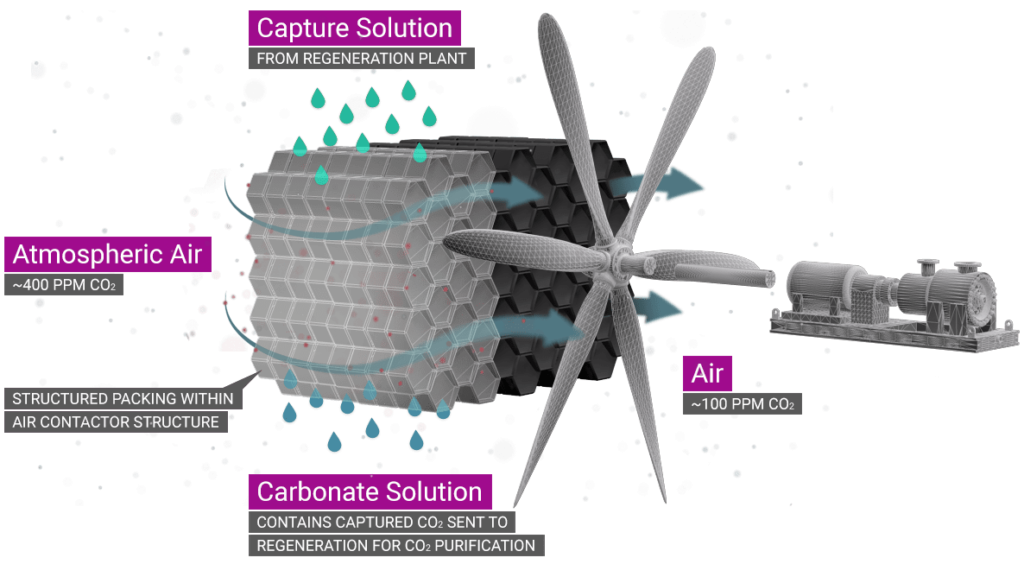

Founded by David Keith, a Harvard University professor of Applied Physics, the technology is designed to capture carbon dioxide (CO2) from ambient air. The Squamish plant began operations in 2015 and now has three years of collected data. It was the first of its kind, a complete direct air capture (DAC) system that could be used to capture CO2 and convert it into liquid hydrocarbon fuel to be mixed with gasoline, or permanently store the greenhouse gas underground.

In the journal article, it describes the evolution of CO2 capture beginning in the 1950s and 60s to be used as a feedstock for hydrocarbon fuels. But in the 1990s researchers started talking about capturing CO2 from the air as a means to mitigate climate change. That’s when the term DAC was coined. At the time no one could calculate what it would cost to capture a ton of CO2. Estimates varied from $50 to $1,000 per ton. But since no one had built a DAC plant to see what the real numbers would be these estimates were entirely speculative.

But now we have the reality check after the Squamish pilot plant has operated for three years. And those numbers are looking pretty good. Running the plant, continuously since startup has achieved CO2 capture at cost levels that are now approaching $100 per ton. This is far removed from the $1,000 or $600 per ton of earlier speculations. And in addition to CO2 capture, since December 2017 the company has started converting the captured gas into fuel, not derived from crude oil, using its trademarked AIR TO FUELS process. In describing the latter, Steve Oldham, CEO of Carbon Engineering, notes “Our clean fuel is fully compatible with existing engines, so it provides the transportation sector with a solution for significantly reducing emissions, either through blending or direct use.” He’s not describing a gasoline-blended fuel, but one that conceivably can be used by any vehicles currently on the road. Although the carbon fuel is 25% more expensive to produce than conventional fuels like gasoline and diesel, unlike them it is very low carbon, and as a Carbon Engineering product, part of the net-zero carbon loop that the company is bringing to market since the emissions the fuel produces can be recaptured by the DAC technology.

The company which initially raised $30 million from government grants, and private investors like Bill Gates, is now in the process of seeking an additional $60 million to build a full-sized commercial DAC plant.

In today’s The Globe and Mail, Global Energy Reporter, Shawn McCarthy describes how DAC could fit into a different world paradigm than the one most of us envision for a low-carbon future. Instead of eliminating fossil fuels, DAC could conceivably make it possible to continue using them with the carbon produced being removed from the air to maintain or reduce CO2 levels within the atmosphere. That would mean the complete electrification of our transportation infrastructure would no longer be necessary.

Oldham describes what this means for the planet in a conversation with The Globe and Mail. “Our low-carbon fuel is entirely compatible with any automobile, any truck, any airplane that exists today. By making the fuel carbon neutral, the entire transportation sector can become carbon neutral without changing all of the infrastructure – we don’t have to get a new car, we don’t have to replace every gas station with an electric grid for charging.”