How comfortable can NASA be with Boeing and the Space Launch System (SLS) after witnessing this latest problem with the Starliner and its stuck propulsion system valves?

It was bad enough with the crash of two Boeing 737 Max 8 jets because of poor software engineering and lax testing by the U.S. Federal Aviation Authority that took the company’s word on the reliability of the modified aircraft. Hundreds of lives were lost.

Now we have the Boeing commercial space taxi, the Starliner, designed to launch astronauts to the International Space Station (ISS). Despite the billions NASA has given Boeing, the company can’t seem to build something equivalent to what SpaceX has achieved on a much smaller budget.

It is good to hear Boeing leadership express the need to focus on the safety of the crew as the reason for pulling the plug on Starliner for the moment. It would have been nice if they had been equally intelligent about the 737 redesigns which gave us the Max 8.

The first orbital flight test of Starliner took place in December 2019. It turned into a fiasco because of a software glitch that caused the spacecraft to fall short of achieving the correct orbit to rendezvous and dock with the ISS. Boeing did a rewrite and patch on the software for the second test flight which was supposed to happen two weeks ago. But on August 3rd, the new and improved Starliner ran into a propulsion system valve problem when several valves did not open in response to automated software commands.

Since the scrubbing of the flight these valves that connect to the retro and safety escape system, as well as the thrusters responsible for in-orbit maneuvering, have remained problematic. Nine of the 13 have been successfully opened by using alternative means to make them work. But four, however, have not. Once again Boeing appears to be demonstrating an inability to engineer a finished product to meet specifications.

Wouldn’t you think that this would give NASA pause when it considers the other big Boeing project the agency is counting on the company to deliver, namely the SLS?

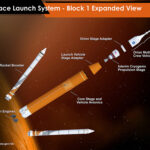

In June of this year, the first version of the rocket, SLS Block 1, a 23-storey monster was finally assembled at Florida’s Kennedy Space Center for the first time. Well overdue and over budget by some $8.75 billion USD, the SLS has grown into an $18 billion boondoggle.

The rocket is complex and non-reusable It consists of thousands of parts including propulsion valves like the ones that have given Starliner the fits. Its first stage links massive propellant tanks to four rocket engines. The core is flanked by two solid rocket boosters which are leftover technology from NASA’s shuttle program.

The rocket has yet to make a test flight which is understandable since each time it lights up it costs $2 billion. Instead, NASA and Boeing are relying on ground testing of the core stage. Fortunately, after a misfire, the most recent burn lasting 8 minutes was successful. The duration of the burn was the time needed to get the rocket to reach space. This achievement prompted NASA to accept delivery in Florida. But no one has tested all the mated disparate parts, which raises the issue: will the full assembly perform equally well?

As I previously stated, non-reusability means every flight in the Artemis Program to return crews to the Moon requires a brand new SLS. The goal, currently, is one flight per year if all goes well. But all going well for Boeing isn’t guaranteed. And with each mistake costing $2 billion, doesn’t that seem to you to be a lot of money spent on a company that is of late suspect? Consider the human factor. Are crews prepared to rely on Boeing’s safety and engineering record of the last few years? Or is there an alternative that the Artemis Program can use that’s affordable and readily available now with little modification?

The SpaceX Falcon Heavy which is flight proven but seldom used is an almost totally reusable system. It is already contracted to launch payloads to the Moon beginning next year. Two years ago, then NASA administrator, Jim Bridenstine, when asked if Falcon Heavy could substitute for the SLS, stated it would require adding an additional stage built by United Launch Alliance which would then be mated to the SpaceX rocket to provide additional payload and thrust. The integration would occur here on Earth and would include a larger payload fairing than the current one used by the Falcon Heavy.

But an even better strategy, that I wrote about in 2019, would borrow from what has been learned in assembling the ISS in low-Earth orbit. It would involve:

- Using a Falcon Heavy to launch an Orion crew module with the reusable portions of the rocket recovered for later missions.

- Additional launches of Falcon Heavy rockets to deliver fuel payloads and a translunar stage to the site where the Orion would be parked in low-Earth orbit.

- Creating a permanent launch platform in low-Earth orbit for translunar spaceships to be assembled before sending them to the Moon.

- Modifying Orion to add a docking assembly, currently not a requirement for the SLS. The technology already exists from SpaceX and NASA and would allow for the coupling of Orion to the translunar rocket.

SpaceX has already demonstrated with its Falcon 9 and Falcon Heavy that it can deliver payloads to space at a fraction of the launch and assembly cost of one SLS. Over the next year, the Falcon Heavy will show it can deliver payloads all the way to the Moon fulfilling both NASA and third-party contracts. And note that none of these missions require the Starship, SpaceX’s fully reusable multistage rocket which is quickly being developed in plain sight in South Texas. Elon Musk has even announced a 2023 circumlunar voyage with passengers and believes he can land human crews on the lunar surface before 2024 ahead of the Artemis Program’s original target date. And with multiple Starships, even the Orion crew module can be considered a redundant and unnecessary expense.

To me, the Boeing SLS project is nothing more than a make-work pork-barrel project, the type favoured by American politicians whose districts receive money for the military and NASA. When you add in Boeing’s record of snafus and engineering miscalculations, let alone the hundreds who died because of the company’s failures, you have to wonder what are the folks in Congress and at NASA thinking?