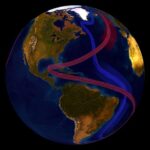

Manufacturing is responsible for 25% of greenhouse gas emissions (GHGs). If we can find a use for all of that carbon we emit into the atmosphere we could go a long way towards mitigating and reversing global warming. Microbes may be the answer.

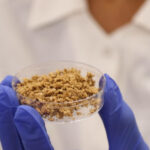

When we ferment grains and grapes to make beer and wine, it is microbes that do most of the work. Called acetogens, the microbes thrive on carbon dioxide (CO2). And we can make them even more effective in taking in GHGs using gas fermentation processes to create fossil-fuel-free rubber, plastic, paints, cosmetics, and more.

Today we rely on fossil fuels to make the kinds of products previously mentioned. But we don’t have to. Instead, we can feed captured carbon monoxide (CO1), CO2 and hydrogen (H2) to acetogens and let these microbes grow in a bioreactor where the gasses are present. The microbes don’t require oxygen. They thrive anaerobically.

The State of Bioreactors

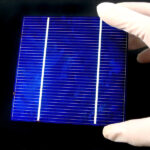

Today’s chemical industries aren’t into bioreactor technology in a big way. But our world is seeking to rapidly reduce the use of fossil fuels to keep global mean temperatures from rising beyond 1.5 Celsius (2.7 Fahrenheit). So it is time to make the switch.

The gasses we need include H2, CO1, and CO2. These are abundant and don’t require us to have to drill wells and pump anything to the surface. Nor do we have to do the refining. We have current technology available to help harvest them either directly from air or water, or from the effluent of industrial and thermal energy plants.

What’s needed to make the conversion a reality?

We already capture CO2 from industrial emissions because we are becoming desperate in attempting to halt global warming. Scrubbers capture CO2 from thermal energy, cement, steel, and other industrial sites and liquefy the gas before piping it to underground storage sites. A more recent innovation has us capturing CO2 directly from the air. Again, the captured gas is intended to be stored underground. But rather than store it, we can use it as bioreactor feedstock.

Today we H2 from water using electrolysis (green hydrogen), and from natural gas (grey hydrogen). Grey hydrogen processes when carbon capture is added are referred to as blue hydrogen. So one can imagine using natural gas as an interim solution not to burn but to create both CO2 and H2, the latter our second bioreactor feedstock.

And finally, today our internal combustion engine technology that we use in transportation produces the third gas, CO1, as a byproduct. To us and animals, CO1 is a poison. But it’s not to microbes. So we can use this technology that currently contributes to global warming in a new way, to capture CO1 for our third bioreactor feedstock.

The beauty of this is current notions of addressing CO2 as a waste gas no longer need apply. If we do it right, we may never need to sequester any CO2 underground. And as for CO1, turning the internal combustion engine technology into a climate change mitigation asset would be a welcome change.

So who is harnessing the power of microbes today?

A few years ago I read about research at Wageningen University, The Netherlands, where microbes were being used to generate electricity. The research involved turning microbes into the equivalent of fuel cells. This was being done by implanting carbon in wet soil and having the bacteria feed on it to produce electricity. Not a bioreactor per se, but what the Wageningen experiment showed is that we can use GHGs, and particularly CO2, in novel ways to generate value in the form of energy and other useful products for our modern world. We should not be constrained, therefore, by our reliance on fossil fuels to support us in the 21st century.

To date, large-scale bioreactors are not in common use. Instead, the technology is found in the food, medical, pharmaceutical and cosmetics industries where it builds biomolecules that are combined with other chemicals to create end products. But what’s needed is a bit of innovative muscle to design bioreactor technology to the point where it can replace existing chemical production methodologies mostly reliant on fossil fuel industry outputs.

The current bioreactor designs are largely variations on vertical column constructs in what is referred to as bubble and airlift. But we need much more experimentation and investment in designs, in using different gaseous substrates, and in acetogen varieties, to see what can be produced that will be useful to us. And we need to do this post-haste to help us in our battle to mitigate global warming.