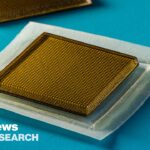

May 11, 2019 – The 3D-Printed Habitat challenge has a declared winner. Our future Martian homes may look like what you see in the picture below. It will be 3D-printed. The winner of the final phase and a $500,000 USD prize is AI SpaceFactory, a New York-based company that is self-described to be a multi-planetary architectural and technology design agency that is building for both Earth and space.

NASA had received competition entries from 60 organizations in 2015. They were competing for $2,000,000 in prize money. Three phases of competition eventually winnowed the field down to two for a final phase with $200,000 going to the runnerup Pennsylvania State University. Both teams had three 10-hour sessions over three days to build a one-third scale version of their design using techniques involving minimal human intervention. That meant robots would do much of the work. Once complete the structures would be put to the test looking at their strength, durability, and leakage.

NASA established several criteria for the competition.

- Materials used could only be locally sourced or recycled from items brought to the planet.

- Anything constructed to meet Mars or Moon requirements would also have to be reproducible for Earth habitations, a nice spinoff.

- The 3D-printer to be used would have to be self-contained, transportable, and deployable on site.

- The habitat was to be pressure-retaining and designed to support living space for up to 4 inhabitants for one year.

- The self-contained structure was to include areas for sleeping, eating and meal preparation, sanitation, recreation, work, and laboratory research, and communication.

- It was also to include all mechanical, electrical, plumbing, and environmental and life support systems requirements.

- The exterior was to include a suit hatch, equipment hatch, at least one viewport, and two combined communications and power instrumentation packages for redundancy.

- The one-third scale printing footprint was to be limited to a space 4.5-meters square and 4.5 meters in height.

The contest rules did include a phase four which would involve creating the full-scale habitat at some future date. It wasn’t clear if that competition would be restricted to the two finalists.

So why did AI SpaceFactory win?

The construction material was a biopolymer basalt composite derived from natural materials found on Mars. It was found to be more durable than concrete yet light and strong.

States David Malott, CEO and Founder of AI SpaceFactory, “We developed these technologies for Space, but they have the potential to transform the way we build on Earth…By using natural, biodegradable materials grown from crops, we could eliminate the building industry’s massive waste of unrecyclable concrete and restore our planet.”

They have called their habitat, TERA, and plan to launch an Indiegogo campaign to raise the capital to start building these habitats here on Earth (see what the designers envisage for use here on Earth in the image below).