August 8, 2018 – If you are not familiar with the term “open source” it refers to publicly-shared specifications and designs whether hardware or software. Most would attribute the beginning of the open source movement to the arrival of the Linux software operating system in 1991. If you are viewing this blog using FireFox then you are using an open-source-created browser from not-for-profit Mozilla, an organization that encourages global participation in the development of its source code. So the announcement in a paper published by University of Toronto researchers, a combination of both scientists and engineers, in the journal Bioprinting will be welcome news to the global community focused on advancing the fields of tissue engineering and regenerative medicine.

Today’s 3D bioprinters are limited by several constraints. The first involves the bioink. The second involves the print heads that inject the bioink. The third involves the medium in which to lay down the ink. The bioink has to nourish the living cells contained within the solution. The print heads must be capable of delivering the bioink solutions keeping the living cells viable. And finally, the medium in which the bioink is deposited must be such that it forms a structural matrix for the growth of the cells to meet the required organ or blood vessel being constructed.

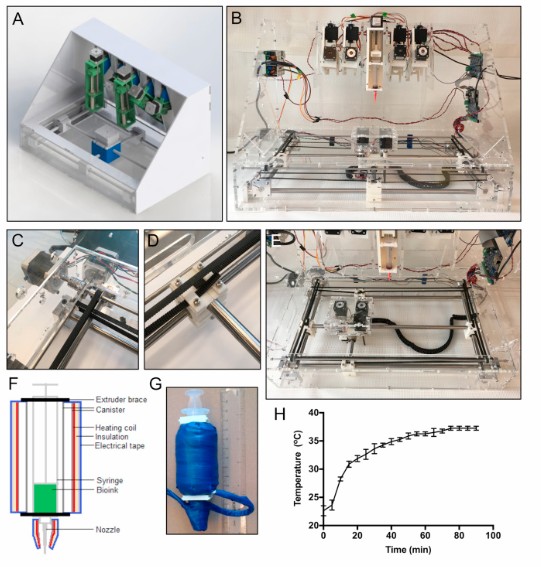

The U. of T. paper describes a functional 3D printer built from custom-designed parts combined with open source controller boards and motors with five print heads, and a Cartesian coordinate XYZ system to plot the 3-dimensional print job where X is width, Y is depth, and Z is height. Traditional inkjet printers are designed for 2D output laying down ink on a sheet of paper. But the added Z dimension is the one that presents the biggest challenge because the method of printing with bioink lays down material using the X and Y axis and then systematically adds layer upon layer to create the Z. Another feature of this open source printer is the print bed which allows the operators to switch out different printing surfaces to address issues like fine temperature regulation during organ or blood vessel construction.

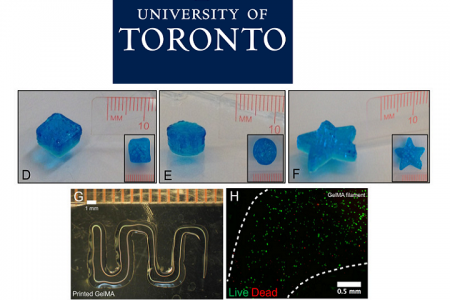

The bioink contains gelatin and readily available Pluronic F-127, a bioreagent suitable for culturing living cells. When doing bioprinting it involves two stages. First, you lay down a material that forms the matrix design for the organ and blood vessel to be constructed. Then second, you follow that with the bioink. The first material is not meant to be permanent. Once the desired organ or blood vessel is constructed, a third step involves flushing away the material in the first step and leaving finished living tissue.

A relative bargain, the cost of the printer amounted to $3,000 CDN in parts and materials. Resolution of the print is between 0.5 and 1 millimeter. In testing the printer was capable of replicating complex vascular tissues with consistency and accuracy.