October 2, 2017 – Lithium’s advantages as a battery medium are many. It is a very light metal. It retains electric charges well and during discharge and recharge isn’t impacted by the memory effect that makes other battery technologies less attractive.

The components of the battery include a lithium cathode, a carbon anode, and an electrolyte solution containing tiny fragments of lithium floating in organic solvents. Each is separated by very thin coatings that serve as partitions. Then the components are compacted together like a grilled ham and cheese sandwich.

Over the years of manufacturing and running billions of lithium-ion batteries in our world we have come to rely on them for powering smartphones, digital cameras, laptop computers, tablets, MP3 players, electric cars, and more. Discharge-recharge cycles happen with hardly ever a problem.

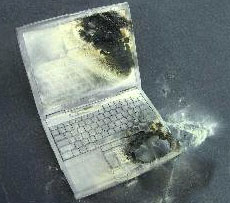

When the problems do happen we can get some pretty spectacular accidents with batteries catching on fire or exploding.

Why does this happen?

There are two common causes for lithium-ion battery accidents. The first happens if the partition coatings have flaws allowing electrolyte containing lithium fragments to leak leading to a short and a fire. The second is known as thermal runaway and is caused by imperfections in the pressurized sandwich and overall containment. Pressure can cause uncontrolled heating and when that happens the results can be either an explosion or fire.

And when a lithium-ion battery catches fire, extinguishing it can be problematic because applying water makes the fire much worse. Only dry powder Class D extinguishers kill a lithium-ion battery fire.

How do we make lithium-ion batteries safer without impacting their performance?

The United States Army has been looking at wearable electronics powered by lithium-ion batteries. and the last thing they want soldiers to experience is a battery igniting while being worn.

Scientists at the Army Research Laboratory, Adelphi, Maryland, along with The Unversity of Maryland have been experimenting with two innovations:

- Altering the electrolyte so that is not based on organic solvents but instead uses a water-salt solution

- Coating the lithium cathode with a hydrophobic gel polymer electrolyte

The combination of the two causes the electrolyte to be expelled when in proximity to the cathode. That eliminates leaks as well as the damage caused by imperfections in the sandwiching of the layers.

The battery they have created, seen in the picture below, is flexible and therefore wearable. Its biggest drawback at the moment is a limited discharge-recharge rate of between 50 and 100 cycles. The researchers are working on improving this to at least 500 cycles in the near future.

They believe their invention has application to other battery technologies including those using sodium-ion, lithium-sulfur, and zinc and magnesium. They also can see applications for electroplating and electrochemical synthesis.

A 50 to 100 cycle recharge-discharge rate is not an inhibitor for the U.S. Army to begin using these lithium-ion batteries. Commercial application, however, is probably still five years away.