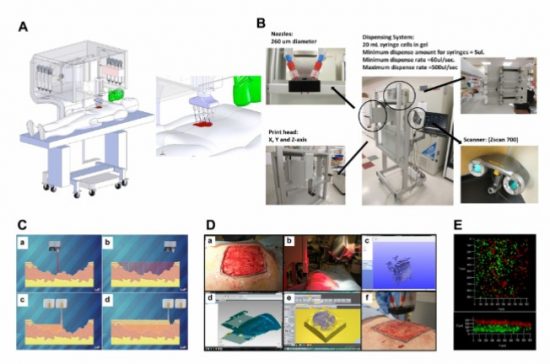

March 3, 2019 – Scientists at the Wake Forest Institute for Regenerative Medicine have invented a mobile system for bio-printing skin to do on-site treatments of wounds. The technology mixes skin cells with a hydrogel for the printer’s ink and then applying the mixture to a wound providing a boost to natural healing.

In a Scientific Reports paper published on February 12th of this year entitled “In Situ Bioprinting of Autologous Skin Cells Accelerates Wound Healing of Extensive Excisional Full-Thickness Wounds,” the authors at the Wake Forest School of Medicine describe how over 7 million patients in the United States experience chronic and episodic wounds leading to $25 billion in annual expenses. Chronic wounds include diabetic, venous, and pressure ulcers. Episodic wounds come from burns and other external non-disease sources. They note that “full thickness” skin injuries are a major source of morbidity and mortality. More than 500,000 Americans annually suffer from burns requiring in-hospital treatment including skin grafts, and for the U.S. military, between 10 and 30% of combat casualties are a result of burn injuries.

The earlier skin wounds get treated leads to greater survivability from burn-related injuries. Currently, skin grafts are the gold standard but getting healthy donor grafts is fraught with potential challenges both in availability and in terms of immune rejection risks. Synthetic materials represent a substitute for grafts but they are costly and cosmetically produce less than desirable results.

A number of other types of technologies have been attempted to heal wounds and accelerate healing. These include spraying or applying liquids with skin cell tissue on wound sites to seed the healing process. The bioprinter takes the above processes several steps further.

- It is portable and can easily be transported.

- It can be used with a wide range of wound types and sizes.

- It can deliver multiple skin cell types precisely where needed.

- It is easily sterilized.

- It is easy to operate.

- It is relatively low cost.