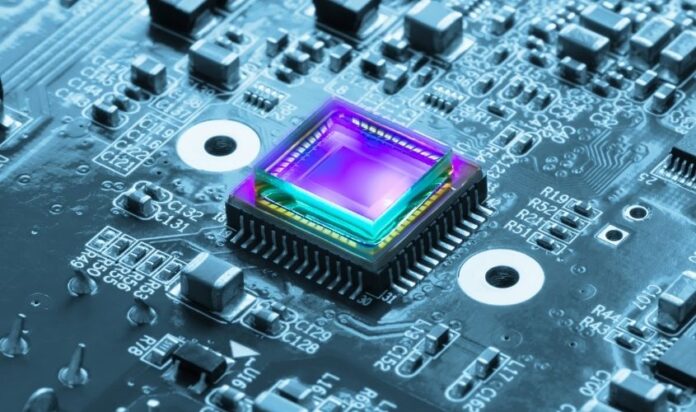

Printed circuit boards (PCBs) are the backbone of modern electronics. Since the PCB first showed up in 1948, the technology has evolved rapidly. Double-sided PCBs marked a sea change just as the introduction of the integrated-circuit silicon chip made it possible to reduce the size of devices. And since the 21st century started to unfold, innovative practices in manufacturing and materials have furthered the evolution of PCBs to meet a growing number of evolving applications.

What are some of these advances?

3D Printing

Also known as additive manufacturing, 3D printing is allowing developers to do custom-built electronics including specialized PCBs. Today there are purpose-built 3-D printers that specialize in PCBs. But even off-the-shelf, generalized 3D printers can be used by hobbyists custom boards using silver-based filament inks.

HDI PCBs and the Demand for More Power

High-Density Interconnector or HDI refers to PCBs with higher wiring density per surface area than typical PCBs. They are designed for more complex tasks and built to handle greater voltage. They feature high-performance substrates and laminates and densities of lines smaller than 65 microns (2.559 mils) and spaces that are less than or equal to 100 micrometres. HDI PCBs are harder to build using traditional etching manufacturing processes because the lines are so close together. As a result lasers end up being used in the builds.

Controlled Impedance

If you are unfamiliar with the term “impedance,” it refers to the total opposition to an alternating current (AC) by an electric circuit. Measured in “ohms” which are units of electrical resistance, a little in the right place can be a good thing.

When dealing with high-speed communication, uncontrolled impedance distorts signals, corrupting them or cutting them off altogether. Designing circuits that account for minor resistance within highly delineated parameters, means signals can be delivered clearly. With demands for higher and higher speeds, controlled impedance has become a prerequisite for PCBs used in cutting-edge applications.

Using PCBs in Augmented Reality Hardware

It’s not easy to design a PCB that fits into an odd-looking pair of glasses or a headset, but that’s the challenge facing PCB manufacturers in delivering augmented and virtual reality applications. To do this manufactures are building moulded boards that can fit with near-eye display technology, giving viewers access to supplemental information while they navigate a real or virtual world.

Flexible PCBs for Haptic Applications

Wearable technology is becoming more than just the donning of a virtual or augmented reality headset. Now it is PCBs that are in clothes and gloves, that track a wearer’s movements and quantify and analyze his or her activity. This is a technology designed to bend but not break.

DuPont’s Pyralux material is an all polyimide double-sided copper-clad laminate for use in the design of flexible PCBs. The growth in wearable haptic technology for use in gaming, recreation, military, medical and scientific applications is exploding creating a market for this new generation of PCBs.