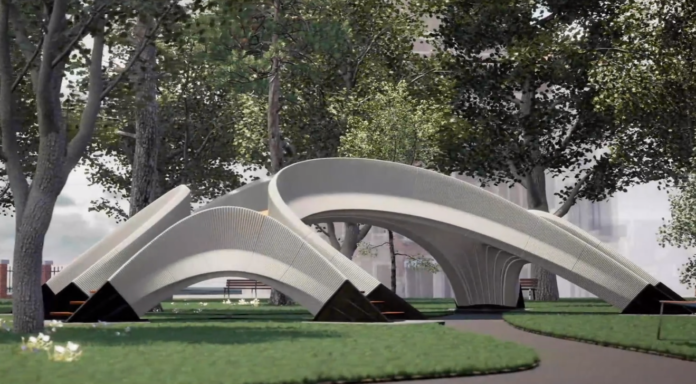

How can it be concrete without rebar? Apparently, it can, while being load-bearing, requiring less material, be seamless and have no need for mortar. At least that’s what has been created by ETH Zurich architecture and engineering school, The Block Research Group, and Zaha Hadid Architects who have built a 3D-printed concrete footbridge named Striatus that now spans a park in Venice, Italy.

Striatus measures 12 by 16 metres (40 to 52 feet) and is constructed using a combination of concrete blocks and 3D-printed concrete. Its designers note that it is the geometry of the design that provides its stability.

Professor Philippe Block of ETH Zurich states, “the name Striatus reflects the bridge’s structural logic and fabrication process. In arched and vaulted structures, material is placed such that forces can travel to the supports in pure compression. Strength is created through geometry, using a fraction of the materials used in conventional concrete beams. This, furthermore, opens a breadth of opportunities to build with lower-strength and in a more ecologically friendly way.”

Unique to this structure which uses no mortar, is the ease in which it can be deconstructed and reassembled at a different location. If no longer needed, the materials can easily be separated and recycled.

The use of 3D printing for the bridge doesn’t follow what we normally think of when looking at additive manufacturing processes. The material used, the concrete ink has been developed by Holcim, a building materials and solutions company that is a leading supplier of cement, aggregates, ready-mix concrete, and now low-carbon material solutions.

CEO of Holcim, Jan Jenisch, notes in a media release that the bridge “was designed by some of the best architectural and creative minds in their fields. It demonstrates the infinite possibilities of 3D Concrete Printing to enable more sustainable, faster and effective building structures, without compromise on aesthetics and functionality. Its digital and circular design uses concrete at its best, with minimal material use and blocks that can be repeatedly reassembled and infinitely recycled.”

The concrete ink was custom-made by Holcim’s research team. It is among a generation of new inks for 3D printers that are a part of the company’s green building solutions which include ECOPact green concrete, ECOPlanet green cement, and recycled construction and demolition waste.

Holcim’s ink recently was used in the construction of a 3D-printed school in Malawi. The walls for the building were erected in 18 hours using 70% less material than if traditional concrete construction techniques were used. Holcim’s concrete inks are also being used to increase the height of wind turbine towers to harvest more energy, partnering with GE Renewable Energy and COBOD, a designer of 3D printers for the construction industry.

If you plan to visit Venice, you have up until November of this year to see Striatus in the Marinaressa Gardens on display during the Venice Architecture Biennale. My guess, it will be deconstructed and recycled after the event.

It was interesting to see the announcement of Striatus, shortly after a 3D-printed steel pedestrian bridge made its debut mid-month over the Oudezijds Achterburgwal canal in Amsterdam.

The trend to 3D-printing using a range of materials now seems well established in architecture and construction. I suspect we will see many more novel materials emerge for builds as this technology matures.