May 6, 2020 – If you are a cement producer, an oil and gas producer, or operate a steel foundry or other materials manufacturing facility, capturing carbon may be the ticket to your economic survival as governments institute restrictions and a price on greenhouse gas emissions. Carbon capture and sequestration (CCS) technology has been with us now for about two decades. From pilot and demonstration add ons to coal-fired powerplants, gas and oil production and refining sites, and fertilizer plants, CCS has been tested with temerity. The first decade of projects have all been described using words like pilot, or demonstration. To date, new and planned projects still are described in these trial words. And although there are a number of operational sites, they are few and far between compared to those described as a proof-of-concept. Many of these first operational carbon capture plants are really not contributing to reducing atmospheric greenhouse gas emissions because the carbon dioxide (CO2) being captured is used for existing oil production by pumping the gas into aging fields to enhance recovery.

The following is a list of some of the CCS projects not defined as test, pilot or study.

- In 2000 a coal gasification process was implemented at Great Plains Synfuels Plant in North Dakota. It has captured around 35 million tons of CO2 since operations began using the gas in enhanced oil recovery operations.

- Since 2008 the Snohvit Storage facility has been capturing CO2 from liquid natural gas facilities in northern Norway and injecting it into offshore storage. 4 million tons has been captured to-date.

- The Chongqing Hechuan coal-fired power plant since 2010 has been capturing 10,000 tons of CO2 annually from the flue gas stream for liquefication and use as an industrial gas.

- In 2013 Air Products in Port Arthur, Texas began capturing CO2 from two steam methane reformers and transporting the gas to existing production fields for enhanced oil recovery.

- In 2013 the Coffeyville Gasification Plant in Kansas began capturing 1 megaton of CO2 per year from fertilizer production and piping it to fields in Oklahoma for enhanced oil recovery.

- In 2013 Petrobras began capturing CO2 from its offshore production wells and reinjecting the gas under the seabed for enhanced oil recovery. By the end of 2017, 7 million tons had been captured and injected into pre-salt offshore fields.

- In 2014 The Boundary Dam coal-fired power plant in Saskatchewan began capturing 1 megaton of CO2 annually and transporting the gas by pipeline to the Aquistore Project for permanent geological storage.

- In 2015, Air Liquide in Port Jerome, Normandy began capturing 100,000 tons of CO2 annually from a hydrogen production facility.

- In 2015, the Quest Project in Alberta began capturing 1 megaton of CO2 per year from an oil sands upgrader. By July 2017 the company announced it had stored 2 million tons permanently in stable underground geological formations.

- In 2016 Abu Dhabi’s Emirates Steel Industries implemented the first commercial CCS facility for the iron and steel industry.

- In 2016 Tuticorin in Chennai, India began capturing 60,000 tons of CO2 annually from the flue gas of a coal-fired power plant with the gas being used as feedstock for soda ash production.

- In 2016 Saga City completed construction of a Toshiba-built carbon capture and utilization system attached to municipal waste incineration, harvesting 10 tons of CO2 per day for use in crop and algae production.

- In 2017 Decatur-based Illinois Industrial began capturing CO2 from a corn-to-ethanol plant with an injection capacity of 1 megaton per year.

- In 2017 Petra Nova began operating a post-combustion CO2 capture system at a power plant near Houston, Texas, producing 1.4 megatons of the gas which was then piped to nearby oilfields for enhanced recovery.

- In 2018 a pulp mill in Saint-Felicien, Quebec began capturing 30 tons of CO2 per day from its softwood kraft pulp mill.

- In 2018 Beijing Shougang began capturing CO2 for a steel production facility and using it to produce fuel-grade ethanol.

- In 2019 Gorgon, an offshore Western Australia gas developer began capturing between 3.4 and 4 megatons of CO2 per year from operations and piping the gas underground into stable geological formations.

As much as these facilities have shown the viability of CCS, it is the road ahead that holds promise for the industry as the power, oil and gas, cement, and materials manufacturing industry sectors pivot towards net-zero carbon by the mid-century.

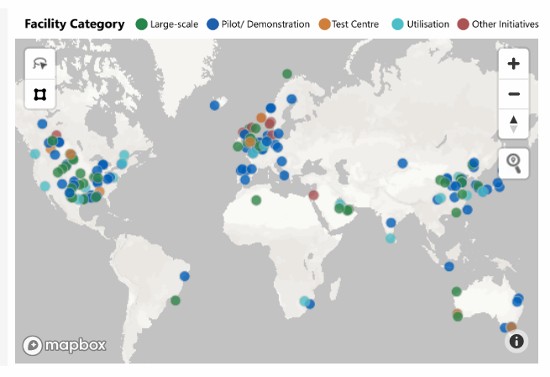

Just how many projects are already in place or planned for can be seen on the map below.

In the most recent IPCC reports on climate change, the international body has declared CCS as a necessary technology to keep mean global atmospheric temperatures from rising 1.5 Celsius (2.4 Fahrenheit) degrees or higher. Speed to implement in this decade is seen as critical. With only 21 operational facilities currently in play, the world needs almost 50 times that number to draw down on CO2 and methane (CH4) emissions that have been added to the atmosphere in the past century-and-a-half. The total number of existing or planned projects, however, remains in the low one-hundreds, far too low to make the needed difference.

And since Houston, Texas, is the oil capital of the United States, the quotation “Houston, we have a problem” seems fitting re CCS global deployment as a climate change mitigator. Those who profess that CCS is the solution need to do much better.