June 6, 2016 – Back in October of 2015 I posted an article about a Calgary-based company, Carbon Engineering, that was harvesting carbon dioxide (CO2) from ambient air. At the time the company had built its first pilot plant in Squamish, British Columbia. At the time the prevailing opinion among scientists and engineers was that harvesting CO2 directly from the atmosphere would be prohibitively expensive, on the order of costing up to $1,000 U.S. per ton.

Since that posting the plant in Squamish is up and running and capturing a ton of CO2 every day. It’s expensive but it’s also a start. Adrian Corless, the company’s CEO states, “we’ve taken existing pieces of industrial equipment and thought about new chemistries to run through them.”

How does CO2 capture work?

Ambient air is passed through a cooling tower containing an alkali solution. The alkali reacts with the CO2 producing potassium carbonate and extracting 75 to 80% of the gas from the air. Calcium hydroxide is combined with the potassium carbonate. The combination is then heated in a kiln which yields solid calcium carbonate (CaCO3) and potassium hydroxide. The latter is recycled to be used again to capture more CO2. The CaCO3 created in this process is a granular version of limestone (see image below).

You can’t have a lot of limestone sludge hanging around unless your in the cement manufacturing business. So Carbon Engineering has created a post capture process that partially releases some of the CO2 back into the atmosphere and uses the remainder to make low-carbon transportation fuel. This synthesized fuel contains 1/3 the carbon content of gasoline and costs up to $1.56 per liter or $6 per gallon. Now no one currently wants to pay that kind of price to operate a vehicle. By scaling up the CO2 capture to megatons rather than a ton per day the cost of the synthesized fuel should drop considerably which will then make technology like this even more attractive to a world seeking a low-carbon future.

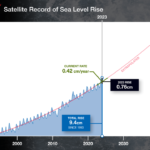

How many plants would we need like this to put a dent in CO2 levels that have breached 400 parts per million in our atmosphere today? A thousand plants capturing a megaton of CO2 per day would yield one gigaton of the gas. That equals about 10% of the annual global carbon emissions produced by the fossil fuel and cement industry today. Current CO2 levels are 43% above what they were at the start of the Industrial Revolution in 1750.

So what about the cost of carbon capture using this technology? To build its Squamish plant Carbon Engineering received $6.2 million U.S. from investors including, among them, Bill Gates. At 365 tons of CO2 captured per year that amounts to about $17,000 per ton. Obviously that number includes all startup costs so until the plant has operated for a few years we really cannot gauge the unit cost accurately. But anyway you look at it in its current state the technology remains prohibitively expensive.

http://www.fastcoexist.com/3044272/world-changing-ideas/clearing-the-air