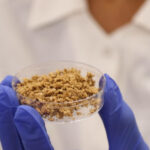

Two University of Tokyo professors, Ippei Maruyama and Takafumi Noguchi, from the Department of Architecture are experimenting with a new building material made from waste concrete, and carbon dioxide (CO2) captured from the air or from industrial emission sources. They recently published their results in the Journal of Advanced Concrete Technology.

The inspiration for this discovery comes from observing how shelled organisms become fossilized over time. This natural process doesn’t require a carbon-intensive process to heat crushed limestone in the making of cement. Instead, the reaction occurs when waste concrete is exposed to water to form calcium carbonate. It doesn’t make as strong a concrete as that which is presently being used in large building construction, but it is durable and resilient enough to be used for small single-family homes.

The goal states Professor Noguchi is to increase the strength and the amount that their new production process can create. Carbon-neutral calcium carbonate concrete could be one answer for the planet in our desire to reduce greenhouse gas emissions and to lower the rise in atmospheric temperatures to keep the mean below 1.5 Celsius (2.7 Fahrenheit).

Why is concrete such an important part of our fight to mitigate global warming?

From a headline on a website come the following words:

“Global Warming Has Concrete Problem When It Comes to CO2.” Why is that? Because, if the production of concrete were a country, it would be third in CO2 emissions only surpassed by China and the U.S., and amounting to more than 2.5 Gigatons annually. Concrete produces 8% of the CO2 emitted annually into the atmosphere. That’s slightly less than emissions from agriculture.

Will concrete come up at the COP26 conference in Glasgow this coming week?

At COP24, a climate conference held in Poland, cement industry guidelines were announced by the GCCA, an organization that represents companies responsible for 30% of cement producing capacity around the world. The guidelines were designed to achieve a 2050 Net Zero decarbonizing result for the cement and concrete industry by mid-century.

The guideline document notes that its industry members have already reduced CO2 emissions in cement production by 20% over the last three decades and plan to accelerate decarbonization to achieve a similar reduction amount by 2030.

To achieve a 25% CO2 reduction per cubic metre of concrete and a 20% reduction per ton of cement by 2030, GCCA members will reduce fossil fuel use, fly ash, and other components of clinkers used in the firing of cement kilns, and increase carbon-capture (CCUS) infrastructure in 10 production facilities.

To get to 2050 there will be a lot more of the same with the wide-scale deployment of CCUS, and implementation of circular economy processes throughout the industry. GCCA members will commit to carbon pricing mechanisms to create a level playing field for the industry. In addition, the industry will prioritize the use of waste and by-products as alternative fuels and materials, will implement a ban on concrete in landfills, and promote the collection, sorting, pre-treatment, recovery, recycling and co-processing of cement and concrete waste.

The GCCA will advocate standards for the adoption of low-carbon cement and concrete products using new chemistries and compositions. That’s one of the areas where Maruyama and Noguchi’s research may pay off big time. (The other impact will be on the reusability of demolished concrete).

A national greenhouse gas accounting and lifecycle analysis mechanism will be implemented for natural CO2 uptake in concrete over its lifetime and at the end of life through recarbonation into permanent CO2 sinks. And finally, the GCCA wants to implement standards for energy performance in buildings that take into account properties such as thermal mass.

Achieving a limited rise of 1.5 Celsius to global mean atmospheric temperatures means business as usual is no longer an option. This is as true for concrete and cement makers around the world as it is for those who produce fossil fuels. One hopes that the latter can take inspiration from the former in making similar commitments to help mitigate anthropogenic causes for global warming.