January 23, 2020 – It is only simulated moondust right now, but the European Space Agency (ESA) is on to a key technological invention that fills one of the two most important needs when humans begin living and working on the Moon and Mars. The first is finding breathable air. The second is finding freshwater.

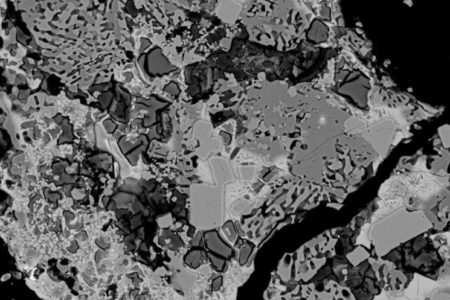

In a January 17th press release ESA described a prototype oxygen generation technology developed at a research centre located in Noordwijk, the Netherlands. Using lunar regolith samples from the Apollo program, the researchers were able to create simulated moondust which contains 40 to 45% oxygen by weight, the single most abundant element bound up in the Moon’s surface.

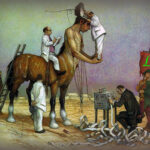

The method to extract oxygen was developed by a UK company, Metalysis, and is called molten salt electrolysis. Metalysis’ process has been designed to extract tantalum and niobium from feedstocks. The oxygen produced is vented as a waste product because with more than 21% of our atmosphere made up of the gas we don’t need to harvest it.

In the Netherlands laboratory, the feedstock used is simulated moon dust to which calcium chloride salt is added. The mix is heated to 950 Celsius (1,742 Fahrenheit), then a current is passed through the material causing it to release oxygen which then is captured. The process also yields the metal alloys for which Metalysis designed its process. On the Moon, however, the captured oxygen is the critical end product of the process. The metal alloys are a nice bonus.

Taking the process out of the Dutch-based laboratory and turning it into a manufacturing plant that could operate on the Moon is ESA’s goal by the mid-2020s. The development of the technology would be crucial to supporting crewed missions to the Moon, and would probably be equally effective on Mars, which surface also contains large volumes of oxygen bound up in the regolith (hence the oxidized red colour of the planet).

Tommaso Ghidini, Head of ESA’s Structures, Mechanisms and Materials Division noted in his comments in the press release that sustained human presence on the Moon is just the first step. Mars is very much on the minds of these researchers in the development of their oxygen extraction process.

The metal alloys left behind after the process could also serve a lunar or Martian colony providing useful fabrication and construction materials. The question of how consistent is the content of the lunar regolith across the entire surface of the Moon has yet to be answered? If it turns out to be reasonably uniform it could lead to the development of a lunar regolith manufacturing industry that produces not just breathable air, but essential metals to support human colonies.

What would be equally interesting is to see if the technology could be adapted to harvest oxygen and metals from asteroids creating a space industry for self-sustaining Deep Space colonies neither bound to a remote planet, nor to one of its satellite moons.

So that gives us one down in terms of basic resources for human presence off-planet. We have oxygen. The next step is finding plentiful supplies of water off-Earth. It appears that may be the easier of the two resource challenges to solve with both Mars and the Moon showing the presence of water ice on or near the surface.