At the Massachusetts Institute of Technology (MIT) there is a new course offering entitled, AI for Computational Design and Manufacturing. It intends to explore and teach the transitioning of today’s manufacturing systems into on-demand, custom-designed processes that use 3D printing or additive manufacturing, and artificial intelligence (AI). The course runs for five days and according to the syllabus includes the following:

- Learning how AI can be used in a manufacturing workflow for process optimization and control.

- Discovering AI/machine learning methods to enable design automation and customization.

- Exploring AI/machine learning methods for design that automatically translate functional specifications of objects to manufacturing.

Could this course have been inspired by NASA, the U.S. space agency, that recently started revealing hardware for spacecraft designed using 3D printing and AI?

Computer-aided-design has been around for years. In my consulting days, I would run into AutoCAD software being used by all my clients that were into manufacturing things. Computer numerical control (CNC) machines were commonly found on every shop floor cranking out parts designed for mass production assembly lines.

But today, with the advent of 3D printers it has become possible to do one-off custom-designed manufacturing. Designers can write some code (an algorithm) and craft unique products that can be individually printed. Going one better, AI can be enlisted to create that code in what is called generative design.

Generative AI Design

Generative design that uses machine learning, a simple form of AI, can begin with an idea expressed in words that can be generated as artwork, and from there be turned into a manufacturing specification blueprint without a significant amount of team devoted to trial and error by human designers and engineers. That’s because machine learning can test multiple iterations of a design idea rendered as art and knowing the material requirements, stress tolerances, and other parameters, create a perfect AI-designed “mousetrap.”

Computers and generative design software represent a twinning of a company’s physical design and manufacturing environment in a virtual space. The virtual or digital twin knows the machines being used, the working environment, the materials, the customer requirements, supplier sourcing and behaviours, and more. The digital twin constantly learns through continuous monitoring of the physical manufacturing environment and from this can either be supervised or unsupervised.

NASA’s Warp Speed Design Process

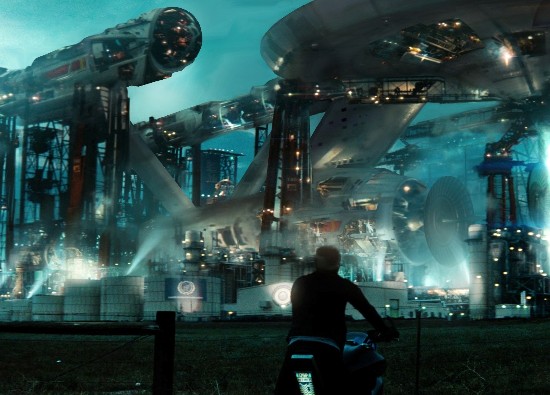

Generative design is fundamentally changing the way NASA is creating parts for future human and robotic space missions. Ryan McClelland in an article published on the FastCompany website told Jesus Diaz, he has drawn inspiration from science fiction shows that feature immense structures in outer space. He noted that current design and manufacturing processes will never get us to Star-Trek-sized spaceships. Instead, it will be parts designed by AI and manufactured using 3D printers that will get us there.

The part seen at the top of the page is one of a number built using generative design which involves providing the AI with geometric and physical specifications and then letting it proceed. The AI is told what the mass requirement is and what G-forces the part will be subjected to and then it begins its work. The parts produced, states McClelland “look somewhat alien and weird, but once you see them in function, it really makes sense.”

Using generative design compresses the entire process from concept to specification to end product. One thing McClelland notes is that AI needs tweaking because the AI NASA is using tends to make things too thin. But the AI comes up with 30 to 40 iterations in an hour after receiving design input which makes the job of NASA engineers a lot easier.

NASA has even started using generative design AI to autonomously design 3D-printed circuits and wires. And although the AI is not ready to build an entire spaceship, after all these are the early days, it is not that far in our future to see generative AI design systems creating a starship like the one being built in the picture below. Will the year be 2100, 2200, or 2300?